The growing global focus on climate change has accelerated the need for sustainable, low-carbon energy solutions. In this context, hydrogen energy has gradually become an important part of the global energy transition. It can be applied in various fields, including transportation, industry, and energy production, while also effectively storing renewable energy and addressing the issue of energy supply fluctuations. However, to realize the widespread use of hydrogen energy, how to efficiently and safely store hydrogen and ensure its stable release when needed remains a challenge that must be solved.

There are several methods for hydrogen energy storage, including compressed hydrogen storage, liquid hydrogen storage, metal hydride storage, and underground hydrogen storage. Each method has its own advantages and limitations, making them suitable for different storage needs and application scenarios. Compressed hydrogen and liquid hydrogen storage are the most commonly used methods, while metal hydride and underground storage are typically used for large-scale and long-term storage.

In this article, we will delve into these hydrogen storage technologies, analyzing their advantages, challenges, and their practical applications and prospects across various industries.

Is Hydrogen Safe?

Hydrogen, as an energy source, has been a subject of safety concerns due to its unique properties. While hydrogen is generally safe when handled properly, it does require specific safety measures to prevent accidents.

Hydrogen’s Properties and Potential Hazards

Hydrogen is a colorless, odorless, and highly flammable gas. It has a very low ignition energy, meaning it can easily ignite when mixed with air in the right concentration (4-75% hydrogen in air). This makes hydrogen highly flammable, which is one of the primary safety concerns. However, hydrogen also has a very low molecular weight, meaning it rises quickly and dissipates into the atmosphere when released, reducing the risk of fire or explosion in outdoor environments.

One of the most significant safety concerns with hydrogen is the potential for leaks, especially in high-pressure storage or transportation systems. Hydrogen gas can leak from even small imperfections in equipment due to its small molecular size. This can lead to dangerous concentrations if not properly managed.

Hydrogen Flame Characteristics

Hydrogen flames are difficult to detect because they emit very little visible light. This poses a risk, especially in the event of a leak in an enclosed space. Hydrogen fires are also hotter than many other fuels, which means they can cause more damage in the event of a fire.

Despite these hazards, hydrogen fires are not as dangerous as they may initially seem. The flames tend to be less radiant than other fuels, meaning they are less likely to cause burns at a distance. Additionally, hydrogen flames are typically invisible in daylight, which can help avoid injuries during controlled burns or managed leaks.

Safety Measures and Technologies

Over the years, significant safety protocols and technologies have been developed to handle hydrogen safely. Some of these include:

Leak Detection: Advanced sensors and leak detection systems have been developed to monitor hydrogen systems for any signs of leakage. These systems are often equipped with automatic shut-off valves to stop the flow of hydrogen if a leak is detected.

Ventilation: Proper ventilation is crucial when working with hydrogen. In confined spaces, hydrogen can accumulate and create an explosive atmosphere. Therefore, adequate ventilation systems must be in place to disperse any leaked gas.

Material Selection: Special materials are used for hydrogen storage tanks and pipelines to prevent leaks and hydrogen embrittlement, which can weaken metals over time. These materials are selected to withstand the high pressures and low temperatures involved in hydrogen storage and transportation.

Flame Arrestors: Devices like flame arrestors are used to prevent the spread of flames in the event of a hydrogen fire. These devices are often integrated into hydrogen systems, particularly in transportation and storage applications.

Hydrogen Safety in Everyday Use

Hydrogen is already in use in a variety of industries, including hydrogen fuel cells, space exploration, and industrial applications. In each of these, safety measures are strictly followed to minimize risks. In fact, hydrogen is often considered safer than some conventional fuels because it dissipates rapidly and is less likely to cause long-lasting fires or environmental harm.

Moreover, hydrogen fuel cell vehicles have passed stringent safety tests. Infrastructure for hydrogen refueling stations is designed with safety as a top priority. Safety standards for hydrogen are constantly improving. Rigorous testing and certification processes ensure that hydrogen systems meet the highest safety standards.

Why is Hydrogen Energy Storage Vital?

As the world shifts towards sustainable energy, hydrogen has become an essential part of the clean energy revolution. It not only helps store energy but also plays a critical role in reducing carbon emissions, making it a key solution in the fight against climate change. However, while renewable energy sources like wind and solar are abundant, they face a significant challenge: intermittency. The sun doesn’t always shine, and the wind doesn’t always blow, making it difficult to rely solely on these sources for continuous power supply.

The Intermittency Issue of Renewable Energy

The biggest challenge of wind and solar energy is their unpredictability.Solar power is strongest during the day, while wind energy depends on weather patterns. This means they cannot provide a constant and stable supply of electricity. Therefore, we need a solution that can store energy when renewable generation is abundant. It should release energy when demand increases or generation slows down.

The Advantages of Hydrogen Storage

Hydrogen energy storage offers a unique solution to this problem. By converting excess electricity into hydrogen gas, we can effectively store energy. The key advantage of hydrogen storage is that it can be stored for long periods without degradation, unlike traditional batteries, which lose efficiency over time. Additionally, the stored hydrogen can be used to generate power, for industrial processes, or even in transportation during peak demand periods.

Long-term Storage with Hydrogen

Hydrogen, as an energy carrier, is capable of long-term energy storage. It allows large amounts of energy to be stored and released when necessary. This makes it a viable option for large-scale renewable energy use. This characteristic is particularly beneficial for countries and industries aiming to increase their reliance on renewable energy. It provides an efficient method for achieving this goal.

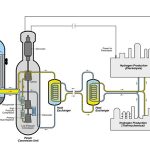

Four Ways of Storing Renewable Hydrogen

Hydrogen storage is one of the most critical components of a hydrogen economy, especially when derived from renewable energy sources. Efficient hydrogen storage solutions allow for the long-term use of excess renewable energy and ensure that hydrogen can be used on-demand, when it’s needed the most. There are several methods to store hydrogen, each with its own advantages and challenges. Below are the four most common ways of storing renewable hydrogen.

Compressed Hydrogen Storage

One of the most widely used methods of hydrogen storage is compression. In this method, hydrogen gas is compressed to very high pressures, typically between 350 bar (5,000 psi) and 700 bar (10,000 psi). The compressed hydrogen is then stored in high-pressure tanks made of lightweight composite materials, such as carbon fiber.

This storage method is commonly used in hydrogen fuel cell vehicles and is also ideal for mobile applications due to its relatively compact design and scalability. Compressed hydrogen storage is an established technology that allows for safe and efficient transportation and storage of hydrogen. However, compressing hydrogen to such high pressures requires a significant amount of energy, and the storage tanks must not only be strong enough to withstand the internal pressure and prevent hydrogen leakage, but also possess good thermal insulation properties, resist hydrogen embrittlement, and avoid causing embrittlement of certain metals. Therefore, the materials and design of the storage tanks must meet strict safety standards to ensure stability during storage and reliability for long-term use.

Liquid Hydrogen Storage

Hydrogen can also be stored in its liquid form by cooling it to extremely low temperatures, around -253°C or -423°F. At this temperature, hydrogen becomes a cryogenic liquid. Liquid hydrogen storage has the advantage of much higher energy density compared to compressed hydrogen. This makes it suitable for large-scale storage and long-distance transport.

However, the process of liquefying hydrogen requires a significant amount of energy, as it is necessary to maintain extremely low temperatures. Additionally, this process requires continuous refrigeration, which can increase costs. The storage of liquid hydrogen requires the use of specially designed cryogenic storage tanks, which are capable of withstanding such low temperatures and preventing heat influx, ensuring that the hydrogen remains in its liquid state.

Metal Hydride Storage

Another method for storing hydrogen is through the use of metal hydrides. This is a chemical process in which hydrogen is absorbed by and chemically bonded to metals or alloys. In this storage method, hydrogen is stored in solid form. The release of hydrogen can be controlled by adjusting the temperature and pressure.

The metal hydride storage system is considered safer than high-pressure storage because hydrogen is stored in solid form, reducing the risk of leaks. Additionally, it has a higher volumetric density, allowing more hydrogen to be stored in a smaller space. However, it requires specific materials and special alloys, making it more costly. Commonly used alloys include magnesium-based alloys (e.g., Mg₂Ni, with a hydrogenation capacity of up to 3.8 wt%, close to the theoretical hydrogen storage capacity), titanium-based alloys (e.g., TiFe, TiNi), zirconium-based alloys (e.g., ZrFe₂), and rare-earth metal alloys (e.g., LaNi₅, NdFe₂). These alloys absorb and release hydrogen at lower temperatures and pressures, but due to the high cost of materials and complex manufacturing processes, their commercial application remains limited.

Underground Hydrogen Storage

Underground hydrogen storage involves storing hydrogen gas in natural geological formations, such as salt caverns, depleted oil and gas reservoirs, or aquifers. This method takes advantage of the earth’s natural ability to contain gases over long periods, providing a low-cost, large-scale storage option for hydrogen.

Underground storage is still under development, but it has significant potential for large-scale, long-term hydrogen storage. This is especially true in areas where surface land is limited or where renewable hydrogen production exceeds immediate demand. The key challenge of underground storage is ensuring the integrity of the storage site and preventing leaks. Additionally, developing the infrastructure to efficiently inject and extract hydrogen is crucial.

In Which Industries is Hydrogen Used?

Hydrogen is a versatile and clean energy carrier with numerous applications across a wide range of industries. It is particularly important in sectors where reducing carbon emissions and improving energy efficiency are critical. In this section, we will explore the various industries where hydrogen is used, including its role in liquid hydrogen applications.

Energy Industry

Hydrogen is increasingly being used as a clean alternative to fossil fuels in the energy sector. One of its most notable uses is in hydrogen fuel cells, which generate electricity through an electrochemical process without combustion, producing only water and heat as byproducts. Fuel cells are used in various applications, from electric vehicles (EVs) to backup power systems and off-grid power solutions.

- Hydrogen for Power Generation: Hydrogen can be used to generate electricity in large-scale power plants, either by burning it directly in turbines or using it in fuel cells. Hydrogen power plants are seen as a potential way to decarbonize the energy sector.

- Hydrogen as a Storage Solution: Hydrogen is also being explored as a means of storing energy. It can store excess renewable energy (such as wind or solar) during periods of low demand and then release it when demand is high, helping to balance the grid and make renewable energy more reliable.

Transportation Sector

After discussing hydrogen storage technologies, we can now see that hydrogen is not only an ideal energy carrier, but its applications also span multiple industries. The potential of hydrogen as a clean energy source is fully demonstrated in various fields such as transportation, industry, and energy.

- Hydrogen Fuel Cell Vehicles (FCVs): These vehicles use hydrogen fuel cells to power electric motors, offering zero emissions, faster refueling times, and longer driving ranges compared to traditional battery electric vehicles (BEVs). Hydrogen-powered buses, trucks, and trains are already in use in several countries, with ongoing investments in infrastructure such as hydrogen refueling stations.

- Aviation: Liquid hydrogen is considered a promising fuel for the aviation sector. Major companies are developing hydrogen-powered aircraft to reduce aviation’s dependence on fossil fuels and cut greenhouse gas emissions. Hydrogen-powered planes could be used for short to medium-haul flights in the future.

- Maritime Transport: Hydrogen is also being tested in the maritime industry, particularly for large ships and vessels. Liquid hydrogen and hydrogen fuel cells could reduce emissions in the maritime sector, which currently relies heavily on oil-based fuels.

Industrial Applications

Hydrogen plays a crucial role in several industrial processes, particularly in the production of chemicals and fertilizers. Some of the key applications include:

- Ammonia Production: Hydrogen is a key raw material in the production of ammonia, which is essential for fertilizers. Ammonia production typically involves a process called the Haber-Bosch process, where hydrogen is combined with nitrogen to form ammonia.

- Petroleum Refining: Hydrogen is used in petroleum refining for hydrotreating and hydrocracking processes, which help remove impurities such as sulfur and improve the quality of fuels.

- Metallurgical Industry: Hydrogen is used as a reducing agent in the production of metals such as steel. Hydrogen can replace carbon-based reducing agents in the traditional blast furnace process, reducing CO2 emissions in steelmaking.

- Hydrogenation: In the food industry, hydrogen is used in hydrogenation processes to convert unsaturated fats into saturated fats, improving shelf life and stability of food products.

Space Exploration

Liquid hydrogen has been a crucial component in space exploration for decades. It is used as a rocket propellant, providing the high energy needed to launch spacecraft into orbit. Liquid hydrogen, combined with liquid oxygen, forms a powerful fuel that has been used in many space missions, including those of NASA’s space shuttles and the Artemis lunar missions.

- Rocket Propulsion: The combination of liquid hydrogen and liquid oxygen (LH2/LOX) is one of the most efficient propellant combinations, providing a high specific impulse and making it ideal for long-range space missions.

- Cryogenic Storage: Liquid hydrogen is used for cryogenic fuel storage in space programs. Its low temperature (-253°C) allows it to be stored for extended periods before use in propulsion systems.

Other Emerging Applications

Hydrogen is also being explored in other emerging sectors, such as:

- Hydrogen as a Replacement for Natural Gas: Hydrogen can be blended with natural gas to reduce the carbon footprint of existing natural gas infrastructure. This is particularly useful in industries like heating and power generation.

- Hydrogen in the Electronics Industry: Hydrogen is used in the electronics industry in processes such as semiconductor manufacturing and the production of flat-panel displays. It serves as a reducing agent in chemical vapor deposition (CVD) processes and other applications requiring high-purity materials.

Conclusion

Hydrogen energy, as a critical component of clean energy, demonstrates tremendous potential across various industries due to its efficient storage and utilization methods. With continuous technological advancements, the safety of hydrogen has been effectively ensured.

If you have any questions regarding hydrogen storage tanks, please feel free to contact us at any time. Minnuo offers free consultations to help you find the best solutions.