With the growing global demand for environmental protection, CNG (Compressed Natural Gas) is quickly becoming an ideal alternative to traditional fuels. As a clean energy source, it is gaining popularity in both public transportation and private vehicles. People choose CNG not only because it significantly reduces carbon emissions but also because it saves costs, making it an economical choice. At the same time, CNG cylinders, the core of this energy solution, are drawing more attention.

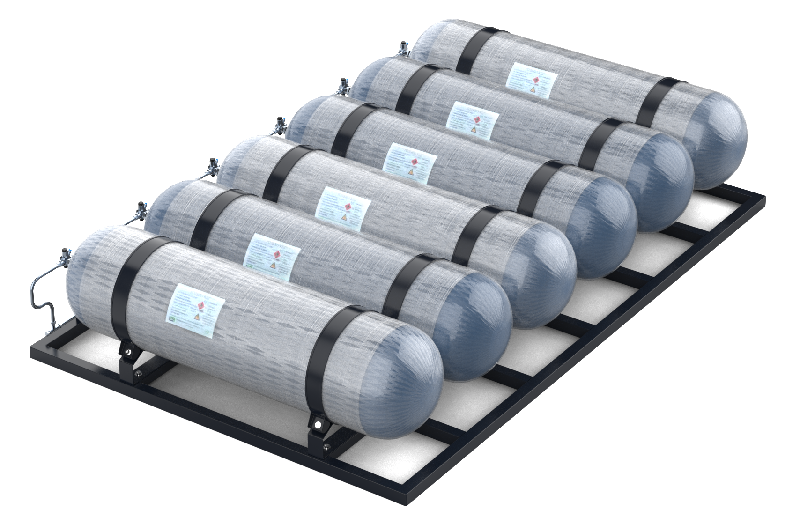

CNG cylinders are essential components for vehicles that use compressed natural gas. They store natural gas under high pressure and deliver it steadily to the engine system during vehicle operation. Built with high-strength materials and advanced manufacturing techniques, these cylinders ensure safety and reliability even under tough conditions. CNG cylinders provide efficient and stable energy support for vehicles, optimize fuel storage and delivery, improve energy utilization, and reduce emissions. They play a vital role in promoting the transition of transportation toward environmental sustainability.

This article will explore various aspects of CNG cylinders, including their key advantages, practical tips for daily use, the necessity and frequency of regular safety inspections, and a comparison with LNG (Liquefied Natural Gas) cylinders.

Comparison Between CNG and LNG Cylinders: Why Choose CNG

Advantages of CNG

Better Environmental Performance

The main component of compressed natural gas (CNG) is methane (CH₄). When burned, it produces much lower levels of carbon dioxide, carbon monoxide, nitrogen oxides, and particulate matter compared to gasoline and diesel. This reduces air pollution and lowers greenhouse gas emissions significantly. Although LNG is also a clean energy source, its production and storage consume large amounts of energy, leading to higher overall carbon emissions compared to CNG. For this reason, CNG is a key choice for achieving green transportation.

Higher Cost Efficiency

CNG is usually cheaper than gasoline and diesel, and its price remains stable over time. For high-usage vehicles like buses and taxis, switching to CNG can save a significant amount of fuel costs. Additionally, unlike LNG, which requires expensive cryogenic storage equipment, CNG cylinders have a simpler design and require a lower initial investment. Minuo’s CNG cylinders, with optimized design and advanced manufacturing, achieve a 42% weight reduction and significantly lower production costs. This provides users with a more economical and efficient solution.

Greater Safety

Unlike gasoline and diesel, CNG quickly disperses into the air when leaked, preventing it from accumulating on the ground and forming flammable gas. On the other hand, LNG must be stored at extremely low temperatures. If leaked, it vaporizes quickly and can cause hazards like frostbite or fire risks.

Wider Applicability

CNG cylinders are suitable for various types of vehicles, such as buses, taxis, and private cars. They are often installed in the trunk, chassis, or interior of vehicles, offering flexibility and convenience. In contrast, LNG is mainly used for long-distance transportation and industrial equipment. Due to its storage and usage requirements, LNG is not suitable for ordinary vehicles. Moreover, the rapidly expanding network of CNG fueling stations further enhances the convenience of using CNG.

Comparison with Traditional Fuels: Why Choose CNG

- Superior Environmental Performance:

CNG emissions are much lower than those of gasoline and diesel, making it a key option for reducing urban air pollution. - Better Cost Efficiency:

Natural gas is affordable and has a stable supply, allowing significant savings in vehicle operating costs over time.

Comparison with LNG: Why Choose CNG

- More Convenient Use:

LNG requires complex cryogenic storage, while CNG does not need special cooling equipment, making it better for daily use. - Simpler Equipment:

CNG cylinders are lightweight and compact. Minuo’s innovative design reduces cylinder weight further, increasing vehicle load capacity and fuel efficiency.

CNG offers clear advantages in environmental performance, safety, cost efficiency, and versatility. It is particularly suitable for buses, taxis, and private vehicles. Minuo’s innovative CNG cylinder technology, with its lightweight design, further enhances fuel performance and provides you with a cleaner, safer, and more economical energy solution.

Key Usage Guidelines for CNG Cylinders

As high-pressure containers, CNG cylinders require strict adherence to safety and operational standards during use. To ensure efficient and safe operation, users must follow proper procedures and conduct regular maintenance and inspections. Here are the professional precautions for using CNG cylinders:

1. Strict Control of Filling Pressure

- Rated Pressure Range: Always keep the filling pressure within the rated design value, such as 200 bar or 250 bar. Overpressure can cause material fatigue or rupture, while underpressure may reduce the vehicle’s range.

- Monitor Equipment Performance: Use refueling systems equipped with high-precision pressure control and overpressure protection. These systems ensure consistent pressure during refueling. Minuo’s CNG cylinders offer highly reliable pressure control, effectively minimizing risks caused by pressure deviations.

2. Standard Refueling Procedures

- Secure Connections: Before refueling, ensure the nozzle and cylinder interface are tightly connected to prevent gas leaks.

- Gradual Pressure Increase: Fill in stages with gradual pressure increases to reduce stress on the cylinder from sudden changes and to better manage the filling volume.

- On-Site Safety Control: Keep the refueling area free of open flames, sparks, or static electricity. Operators should wear protective gear and maintain a safe distance.

3. Storage and Operating Environment Requirements

- Temperature Management: Avoid exposing cylinders to extreme temperatures. High temperatures, such as prolonged parking under direct sunlight, can cause abnormal internal pressure increases. Low temperatures may impact material performance and gas release efficiency. Operate within the recommended range, typically -20°C to 60°C.

- Corrosion Prevention: Store cylinders and accessories in dry, ventilated areas. Avoid contact with chemicals, salt, or moisture to reduce corrosion and material aging.

4. Dynamic Monitoring and Component Replacement

- Real-Time Monitoring: Equip cylinders with real-time monitoring systems to track key parameters like pressure, temperature, and flow. This ensures any abnormal conditions are detected and addressed promptly.

- Replacement of Key Components: Replace seals, valves, and other wear-prone components regularly. If inspections reveal reduced sealing or flow control performance, install high-quality replacements immediately to maintain stable cylinder operation.

Safety Inspection Cycles for CNG Cylinders

1. Initial Inspection

Every CNG cylinder must undergo strict inspection before leaving the factory. This stage includes the following checks:

- Visual Inspection: Examine the cylinder’s surface for visible damage, cracks, dents, or other defects.

- Pressure Testing: Test the cylinder at 1.5 to 2 times its design pressure to ensure it can withstand the required pressure without deformation or leakage.

- Leak Test: Confirm that the cylinder does not leak gas at its rated working pressure.

Cylinders that pass the initial inspection receive a serial number and a test certificate. This ensures proper tracking and management in the future.

2. Regular Inspection

Depending on the design standards and operating environment, CNG cylinders usually need inspection every 3 to 5 years. The inspection includes:

- Visual and Dimensional Checks: Check for surface corrosion, wear, cracks, or detachment of the wrap layer. Measure the cylinder dimensions to confirm they are within the design range.

- Hydrostatic Test: Fill the cylinder with water and apply test pressure higher than its working pressure (usually 1.5 to 2 times the rated pressure). Check for leaks, deformation, or abnormalities.

- Residual Gas Check: Inspect the interior of the cylinder for impurities or corrosive residues to ensure the inner wall remains intact.

- Leak Test: Test all connections and valves under working pressure to confirm there is no gas leakage.

Cylinders that pass regular inspections receive a new certification label or marking. The test date, testing agency, and next inspection date are also recorded.

3. Special Inspection

In specific situations, cylinders require additional checks:

- After Abnormal Events: Perform a full inspection if the cylinder experiences impacts, falls, or fire, to confirm it is still safe to use.

- Frequent Use: Reduce the inspection interval for high-usage cylinders, such as those in buses or long-haul vehicles, to every 2 to 3 years.

- End of Design Life: Retire cylinders after their design life (typically 15 to 20 years). If extending the service life is necessary, have a professional agency conduct a special assessment.

4. Importance of Regular Inspections

- Ensure Cylinder Safety: Inspections help identify and resolve potential hazards such as micro-cracks, fatigue damage, or corrosion that may develop during long-term use.

- Improve Operational Efficiency: Removing impurities and residues during inspections enhances gas delivery efficiency and extends equipment lifespan.

- Maintain Compliance: Following inspection schedules not only meets legal requirements but also ensures operational qualifications and vehicle insurance validity.

Minnuo provides professional inspection services and support to keep cylinders compliant with safety standards:

- Minnuo CNG cylinders, designed using finite element analysis, offer superior pressure resistance and fatigue life, reducing the likelihood of issues during regular inspections.

- Integrated smart sensing systems allow real-time cylinder monitoring and early risk warnings, optimizing inspection schedules.

- A global network of professional inspection centers makes it convenient for customers to manage cylinder testing and maintenance.

Frequently Asked Questions

1. How to Check for CNG Cylinder Leaks?

CNG cylinder leaks pose a direct threat to vehicle safety, so regular checks are essential. Common methods include:

- Visual Inspection: Look for cracks, dents, or damage on the cylinder surface. Pay close attention to the seals at connections, valves, and pipelines.

- Soap Water Test: Apply soapy water to connection points and check for bubbles, which indicate leaks.

- Electronic Detectors: Use specialized gas detection equipment to quickly and accurately identify leak locations and gas concentration.

- Pressure Monitoring: Close the cylinder valve and observe if the pressure gauge shows a continuous drop.

If you detect a leak, stop using the cylinder immediately and contact a professional service provider for repair or replacement. Never operate the cylinder with a known leak.

2. Why Do CNG Cylinders Need Regular Replacement?

CNG cylinders can degrade over time due to fatigue, corrosion, or aging, which can lead to safety risks:

- Material Fatigue: Continuous pressure cycles can create micro-cracks, weakening the cylinder’s ability to withstand pressure.

- Corrosion and Aging: Environmental moisture, chemicals, or internal residues can corrode the surface or damage the inner walls.

- Regulatory Requirements: Most cylinders have a design life of 15 to 20 years. Even if they appear intact, they must be retired when their lifespan ends.

- Technological Advances: Newer cylinders are lighter, safer, and more durable. For example, Minuo’s lightweight design and patented technology improve performance while reducing operating costs.

Conclusion

With the rise of green transportation and growing environmental awareness, CNG cylinders have become a core component of clean energy vehicles. They not only store and transport compressed natural gas but also play a vital role in improving fuel efficiency and reducing carbon emissions. Proper operation, regular inspections, and timely replacements are essential for using and maintaining CNG cylinders. These steps are fundamental for ensuring safety, increasing energy efficiency, and extending equipment lifespan.

As a leading manufacturer, Minnuo provides users with safe and reliable solutions through lightweight designs, high-precision pressure control technology, and intelligent monitoring systems. These innovations help enhance operational efficiency while advancing green transportation.

In the journey toward a low-carbon and environmentally friendly future, CNG cylinders serve as both a bridge for energy transition and a safeguard for sustainable travel. Choosing CNG and choosing Minnuo means choosing safety, efficiency, and a future of sustainable development.