In the context of a global energy transition, crude oil remains an indispensable resource for industries, transportation, and chemical production. However, crude oil extracted from oil fields varies significantly in quality, often containing sulfur compounds, carbon impurities, and water that hinder its direct use. These impurities can damage equipment and degrade the performance of end products. Improving the quality of crude oil is not only essential for maximizing energy efficiency but also crucial for enabling environmentally responsible production and reducing pollution.

The methods to improve the quality of crude oil after extraction are actually quite straightforward. For example, reactors can remove excess sulfur and carbon, making the oil cleaner; electrochemical technology can separate water and salts, protecting equipment from corrosion. Heavy oil can be made lighter and more usable through cracking, and with the addition of gas stripping and distillation, impurities naturally disappear.

So, how can the quality of crude oil be effectively enhanced? This article will provide an in-depth technical overview of the key steps involved in refining crude oil.

Challenges in Crude Oil Quality Improvement

High Sulfur Content: Many crude oils contain excessive sulfur compounds, which release harmful sulfur dioxide (SO₂) when burned, causing environmental pollution.

High Carbon Impurities: Excessive carbon impurities reduce combustion efficiency and complicate downstream processing.

Water and Salt Contamination: Water and salts in crude oil can corrode refining equipment, increasing maintenance costs.

High Viscosity and Poor Flowability: Heavy crude oils with high viscosity and poor flowability are challenging to transport and process.

To address these issues, the oil industry employs a variety of advanced technologies, among which desulfurization and decarbonization using reactors play a pivotal role. Below, we will explore multiple methods for improving crude oil quality.

Four Key Technologies to Enhance Crude Oil Quality

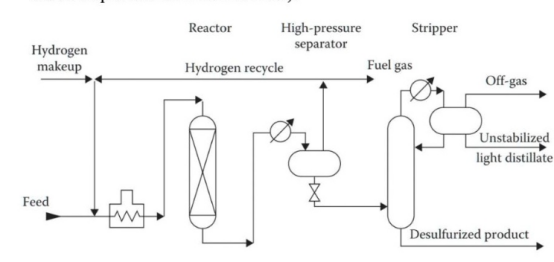

1. Desulfurization and Decarbonization in Reactors: A Core Process

Reactors are highly efficient chemical processing units widely used for desulfurization and decarbonization. In this method, crude oil is mixed with catalysts under high-temperature and high-pressure conditions to facilitate the breakdown or transformation of sulfur compounds and carbon impurities.

Technical Principles:

- Desulfurization: Sulfur compounds in crude oil react with hydrogen in the reactor to form hydrogen sulfide (H₂S), which is then captured using absorption columns, effectively removing sulfur.

- Decarbonization: Heavy carbon-chain compounds are cracked into lighter fractions in the presence of catalysts, thereby improving oil quality.

Advantages:

- Reduces the impact of sulfur and carbon impurities on downstream processes.

- Enhances combustion performance and lowers pollutant emissions.

- Increases the market value of crude oil.

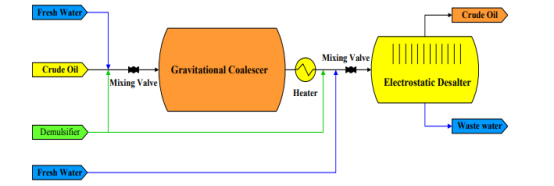

2. Electrochemical Dehydration and Desalting

Electrochemical treatment is primarily used for the preliminary purification of crude oil to remove water and salt contamination. By applying an electric field, the separation efficiency of water and salts is significantly enhanced.

Process Flow:

- Crude oil is pre-heated and allowed to settle, releasing a portion of the water and salts.

- The mixture then enters an electrostatic treatment zone, where charged salt molecules and water droplets are attracted to electrodes and separated effectively.

Results:

- Protects refining equipment and reduces corrosion risks.

- Improves processing efficiency and extends equipment lifespan.

3. Cracking and Upgrading Heavy Crude Oil

Heavy crude oil is often considered “low-value oil” due to its high viscosity and low flowability. However, modern cracking technologies can convert it into lighter, higher-value products.

Technology Classifications:

- Thermal Cracking: Uses high temperatures to break long-chain hydrocarbons into shorter ones.

- Catalytic Cracking: Employs specific catalysts to enable more efficient cracking at lower temperatures.

- Hydrocracking: Conducted in a hydrogen-rich environment to simultaneously crack and improve combustion characteristics.

Significance:

- Enhances the market applicability of crude oil products.

- Meets the demand for high-quality products such as aviation fuel and automotive diesel.

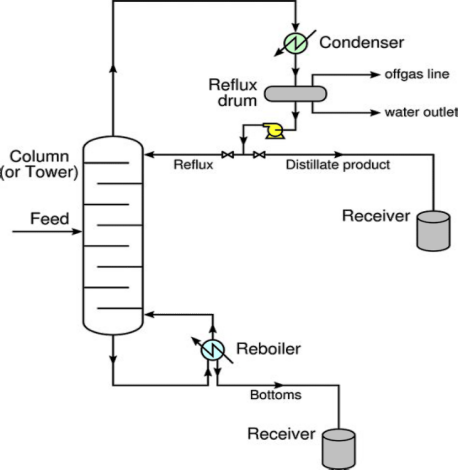

4. Gas Stripping and Distillation for Impurity Removal

Gas stripping and distillation are classic oil purification methods primarily used to remove volatile impurities from both light and heavy crude oils.

Technical Principles:

- Gas Stripping: Involves introducing inert gases to extract unstable components from crude oil.

- Distillation: Separates crude oil into various fractions (e.g., gasoline, diesel, and fuel oil) based on the differences in boiling points of its components.

Technical Highlights:

- Precisely separates oil fractions, improving refining efficiency.

- Reduces impurity content and enhances stability in downstream processing.

How to Choose the Best Oil Quality Improvement Method?

The choice of specific technology depends on the characteristics of the crude oil and the end-use requirements:

- Crude Oil Quality: For oil fields with high sulfur content, prioritizing reactor-based desulfurization is essential.

- End-Use Applications: If light oil products are needed, cracking and upgrading technologies should be prioritized.

- Environmental Standards: Gas stripping and impurity removal technologies are effective in meeting stringent environmental requirements.

- Equipment Compatibility: For example, electrochemical desalting technology requires precise equipment, and its suitability should be carefully evaluated.

Conclusion: Striking a Balance Between Technology and Demand

Every step in crude oil quality improvement is a meticulous optimization process, transforming raw material into refined products. Technologies such as reactor-based desulfurization and decarbonization, electrochemical desalting, heavy oil cracking, and gas stripping work in concert to create tailored solutions for different types of crude oil.

Whether the goal is to increase energy efficiency or reduce pollutant emissions, innovation in technology remains the driving force for progress in the oil industry. If you have any questions about crude oil quality improvement or wish to learn more about reactor-related equipment, please feel free to contact MINNUO. We are committed to providing professional and practical solutions tailored to your needs!