High Pressure Gas Cylinders

Industrial Gas Cylinder Supplier & Custom OEM Services

Leading Chinese manufacturer with 37 years of experience, providing top-quality industrial gas cylinders. Tailored for bulk buyers with custom OEM options and storage solutions.

High Pressure Gas Cylinders

Industrial Gas Cylinder Supplier & Custom OEM Services

Leading Chinese manufacturer with 37 years of experience, providing top-quality industrial gas cylinders. Tailored for bulk buyers with custom OEM options and storage solutions.

High Pressure Gas Cylinders

——Quality, Safety, and Customization for Your Business——

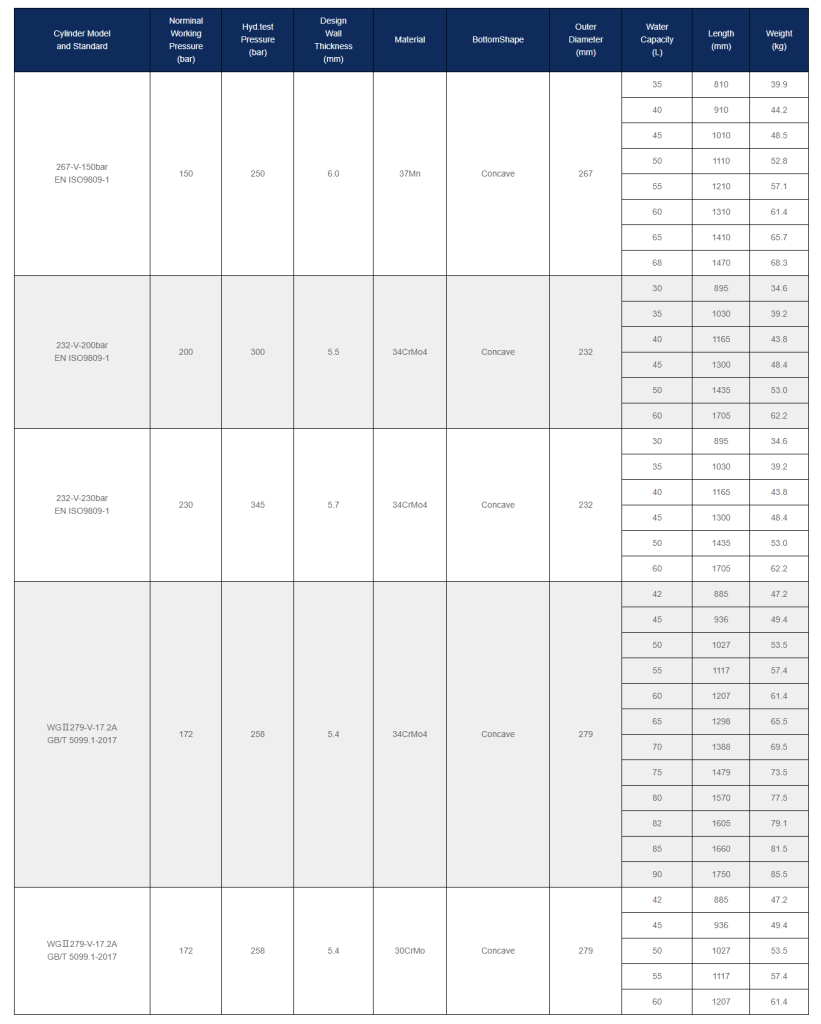

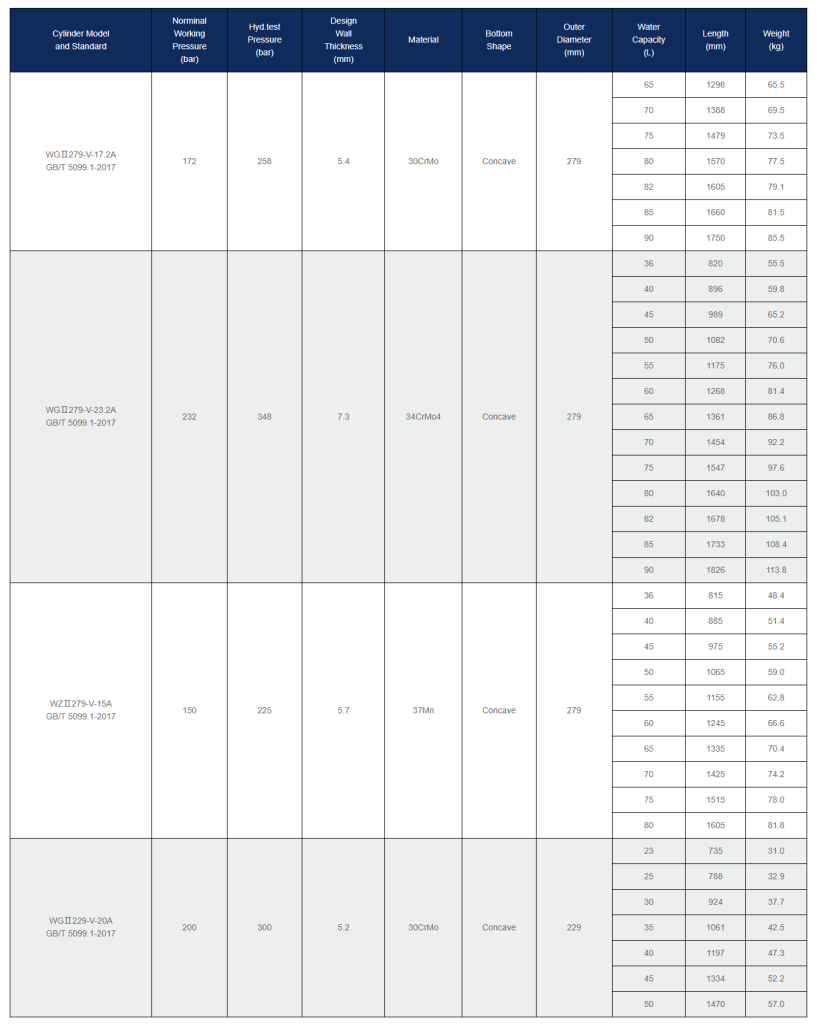

Cylinders Specifications

| Cylinder Model and Standard |

Norminal Working Pressure (bar) |

Hyd.test Pressure (bar) |

Design Wall Thickness (mm) |

Material | BottomShape | Outer Diameter (mm) |

Water Capacity (L) |

Length (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 267-V-150bar EN ISO9809-1 |

150 | 250 | 6.0 | 37Mn | Concave | 267 | 35 | 810 | 39.9 |

| 40 | 910 | 44.2 | |||||||

| 45 | 1010 | 48.5 | |||||||

| 50 | 1110 | 52.8 | |||||||

| 55 | 1210 | 57.1 | |||||||

| 60 | 1310 | 61.4 | |||||||

| 65 | 1410 | 65.7 | |||||||

| 68 | 1470 | 68.3 | |||||||

| 232-V-200bar EN ISO9809-1 |

200 | 300 | 5.5 | 34CrMo4 | Concave | 232 |

30 | 895 | 34.6 |

| 35 | 1030 | 39.2 | |||||||

| 40 | 1165 | 43.8 | |||||||

| 45 | 1300 | 48.4 | |||||||

| 50 | 1435 | 53.0 | |||||||

| 60 | 1705 | 62.2 | |||||||

| 232-V-230bar EN ISO9809-1 |

230 | 345 | 5.7 | 34CrMo4 | Concave | 232 |

30 | 895 | 34.6 |

| 35 | 1030 | 39.2 | |||||||

| 40 | 1165 | 43.8 | |||||||

| 45 | 1300 | 48.4 | |||||||

| 50 | 1435 | 53.0 | |||||||

| 60 | 1705 | 62.2 | |||||||

| WGⅡ279-V-17.2A GB/T 5099.1-2017 |

172 | 258 | 5.4 | 34CrMo4 | Concave | 279 |

42 | 885 | 47.2 |

| 45 | 936 | 49.4 | |||||||

| 50 | 1027 | 53.5 | |||||||

| 55 | 1117 | 57.4 | |||||||

| 60 | 1207 | 61.4 | |||||||

| 65 | 1298 | 65.5 | |||||||

| 70 | 1388 | 69.5 | |||||||

| 75 | 1479 | 73.5 | |||||||

| 80 | 1570 | 77.5 | |||||||

| 82 | 1605 | 79.1 | |||||||

| 85 | 1660 | 81.5 | |||||||

| 90 | 1750 | 85.5 | |||||||

| WGⅡ279-V-17.2A GB/T 5099.1-2017 |

172 | 258 | 5.4 | 30CrMo | Concave | 279 |

42 | 885 | 47.2 |

| 45 | 936 | 49.4 | |||||||

| 50 | 1027 | 53.5 | |||||||

| 55 | 1117 | 57.4 | |||||||

| 60 | 1207 | 61.4 |

| Cylinder Model and Standard |

Norminal Working Pressure (bar) |

Hyd.test Pressure (bar) |

Design Wall Thickness (mm) |

Material | Bottom Shape |

Outer Diameter (mm) |

Water Capacity (L) |

Length (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| WGⅡ279-V-17.2A GB/T 5099.1-2017 |

172 | 258 | 5.4 | 30CrMo | Concave | 279 | 65 | 1298 | 65.5 |

| 70 | 1388 | 69.5 | |||||||

| 75 | 1479 | 73.5 | |||||||

| 80 | 1570 | 77.5 | |||||||

| 82 | 1605 | 79.1 | |||||||

| 85 | 1660 | 81.5 | |||||||

| 90 | 1750 | 85.5 | |||||||

| WGⅡ279-V-23.2A GB/T 5099.1-2017 |

232 | 348 | 7.3 | 34CrMo4 | Concave | 279 | 36 | 820 | 55.5 |

| 40 | 896 | 59.8 | |||||||

| 45 | 989 | 65.2 | |||||||

| 50 | 1082 | 70.6 | |||||||

| 55 | 1175 | 76.0 | |||||||

| 60 | 1268 | 81.4 | |||||||

| 65 | 1361 | 86.8 | |||||||

| 70 | 1454 | 92.2 | |||||||

| 75 | 1547 | 97.6 | |||||||

| 80 | 1640 | 103.0 | |||||||

| 82 | 1678 | 105.1 | |||||||

| 85 | 1733 | 108.4 | |||||||

| 90 | 1826 | 113.8 | |||||||

| WZⅡ279-V-15A GB/T 5099.1-2017 |

150 | 225 | 5.7 | 37Mn | Concave | 279 | 36 | 815 | 48.4 |

| 40 | 885 | 51.4 | |||||||

| 45 | 975 | 55.2 | |||||||

| 50 | 1065 | 59.0 | |||||||

| 55 | 1155 | 62.8 | |||||||

| 60 | 1245 | 66.6 | |||||||

| 65 | 1335 | 70.4 | |||||||

| 70 | 1425 | 74.2 | |||||||

| 75 | 1515 | 78.0 | |||||||

| 80 | 1605 | 81.8 | |||||||

| WGⅡ229-V-20A GB/T 5099.1-2017 |

200 | 300 | 5.2 | 30CrMo | Concave | 229 | 23 | 735 | 31.0 |

| 25 | 788 | 32.9 | |||||||

| 30 | 924 | 37.7 | |||||||

| 35 | 1061 | 42.5 | |||||||

| 40 | 1197 | 47.3 | |||||||

| 45 | 1334 | 52.2 | |||||||

| 50 | 1470 | 57.0 |

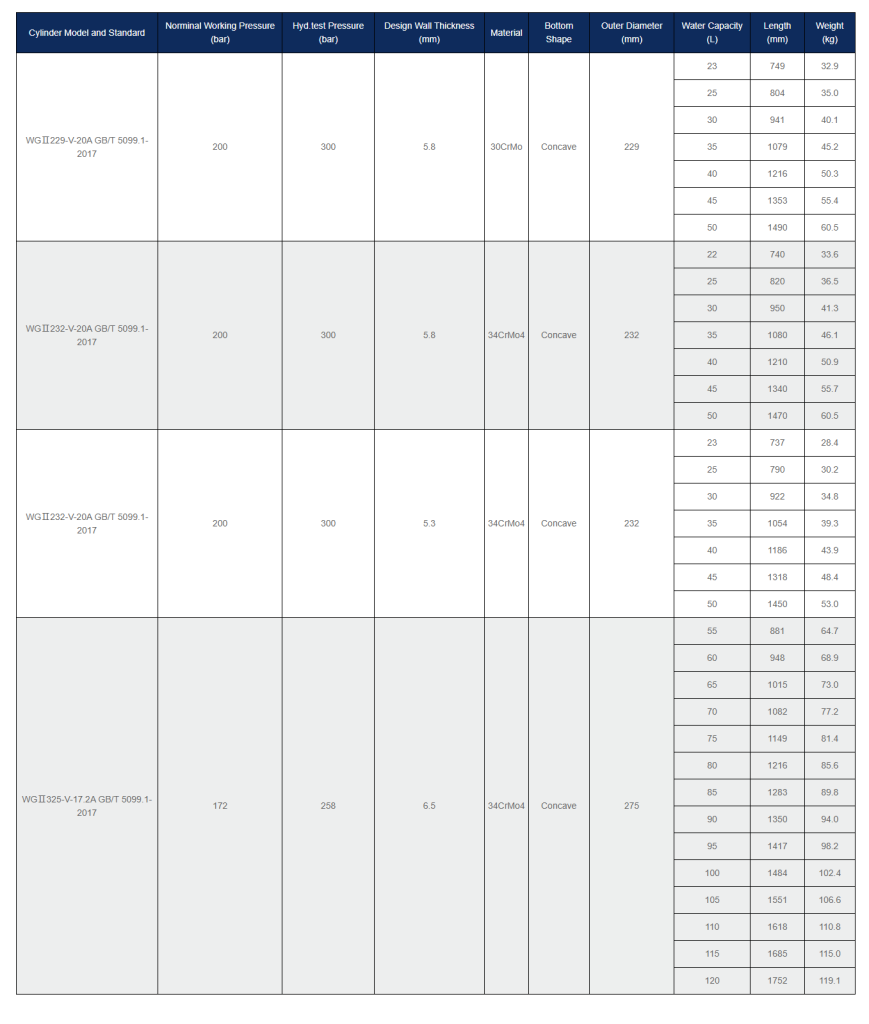

| Cylinder Model and Standard |

Norminal Working Pressure (bar) |

Hyd.test Pressure (bar) |

Design Wall Thickness (mm) |

Material | Bottom Shape |

Outer Diameter (mm) |

Water Capacity (L) |

Length (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| WGⅡ229-V-20A GB/T 5099.1-2017 |

200 | 300 | 5.8 | 30CrMo | Concave | 229 | 23 | 749 | 32.9 |

| 25 | 804 | 35.0 | |||||||

| 30 | 941 | 40.1 | |||||||

| 35 | 1079 | 45.2 | |||||||

| 40 | 1216 | 50.3 | |||||||

| 45 | 1353 | 55.4 | |||||||

| 50 | 1490 | 60.5 | |||||||

| WGⅡ232-V-20A GB/T 5099.1-2017 |

200 | 300 | 5.8 | 34CrMo4 | Concave | 232 | 22 | 740 | 33.6 |

| 25 | 820 | 36.5 | |||||||

| 30 | 950 | 41.3 | |||||||

| 35 | 1080 | 46.1 | |||||||

| 40 | 1210 | 50.9 | |||||||

| 45 | 1340 | 55.7 | |||||||

| 50 | 1470 | 60.5 | |||||||

| WGⅡ232-V-20A GB/T 5099.1-2017 |

200 | 300 | 5.3 | 34CrMo4 | Concave | 232 |

23 | 737 | 28.4 |

| 25 | 790 | 30.2 | |||||||

| 30 | 922 | 34.8 | |||||||

| 35 | 1054 | 39.3 | |||||||

| 40 | 1186 | 43.9 | |||||||

| 45 | 1318 | 48.4 | |||||||

| 50 | 1450 | 53.0 | |||||||

| WGⅡ325-V-17.2A GB/T 5099.1-2017 |

172 | 258 | 6.5 | 34CrMo4 | Concave | 275 | 55 | 881 | 64.7 |

| 60 | 948 | 68.9 | |||||||

| 65 | 1015 | 73.0 | |||||||

| 70 | 1082 | 77.2 | |||||||

| 75 | 1149 | 81.4 | |||||||

| 80 | 1216 | 85.6 | |||||||

| 85 | 1283 | 89.8 | |||||||

| 90 | 1350 | 94.0 | |||||||

| 95 | 1417 | 98.2 | |||||||

| 100 | 1484 | 102.4 | |||||||

| 105 | 1551 | 106.6 | |||||||

| 110 | 1618 | 110.8 | |||||||

| 115 | 1685 | 115.0 | |||||||

| 120 | 1752 | 119.1 |

| Cylinder Model and Standard | Norminal Working Pressure (bar) | Hyd.test Pressure (bar) | Design Wall Thickness (mm) | Material | Bottom Shape | Outer Diameter (mm) | Water Capacity (L) | Length (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| WGⅡ229-V-20A GB/T 5099.1-2017 | 200 | 300 | 5.8 | 30CrMo | Concave | 229 | 23 | 749 | 32.9 |

| 25 | 804 | 35.0 | |||||||

| 30 | 941 | 40.1 | |||||||

| 35 | 1079 | 45.2 | |||||||

| 40 | 1216 | 50.3 | |||||||

| 45 | 1353 | 55.4 | |||||||

| 50 | 1490 | 60.5 | |||||||

| WGⅡ232-V-20A GB/T 5099.1-2017 | 200 | 300 | 5.8 | 34CrMo4 | Concave | 232 | 22 | 740 | 33.6 |

| 25 | 820 | 36.5 | |||||||

| 30 | 950 | 41.3 | |||||||

| 35 | 1080 | 46.1 | |||||||

| 40 | 1210 | 50.9 | |||||||

| 45 | 1340 | 55.7 | |||||||

| 50 | 1470 | 60.5 | |||||||

| WGⅡ232-V-20A GB/T 5099.1-2017 | 200 | 300 | 5.3 | 34CrMo4 | Concave | 232 | 23 | 737 | 28.4 |

| 25 | 790 | 30.2 | |||||||

| 30 | 922 | 34.8 | |||||||

| 35 | 1054 | 39.3 | |||||||

| 40 | 1186 | 43.9 | |||||||

| 45 | 1318 | 48.4 | |||||||

| 50 | 1450 | 53.0 | |||||||

| WGⅡ325-V-17.2A GB/T 5099.1-2017 | 172 | 258 | 6.5 | 34CrMo4 | Concave | 275 | 55 | 881 | 64.7 |

| 60 | 948 | 68.9 | |||||||

| 65 | 1015 | 73.0 | |||||||

| 70 | 1082 | 77.2 | |||||||

| 75 | 1149 | 81.4 | |||||||

| 80 | 1216 | 85.6 | |||||||

| 85 | 1283 | 89.8 | |||||||

| 90 | 1350 | 94.0 | |||||||

| 95 | 1417 | 98.2 | |||||||

| 100 | 1484 | 102.4 | |||||||

| 105 | 1551 | 106.6 | |||||||

| 110 | 1618 | 110.8 | |||||||

| 115 | 1685 | 115.0 | |||||||

| 120 | 1752 | 119.1 |

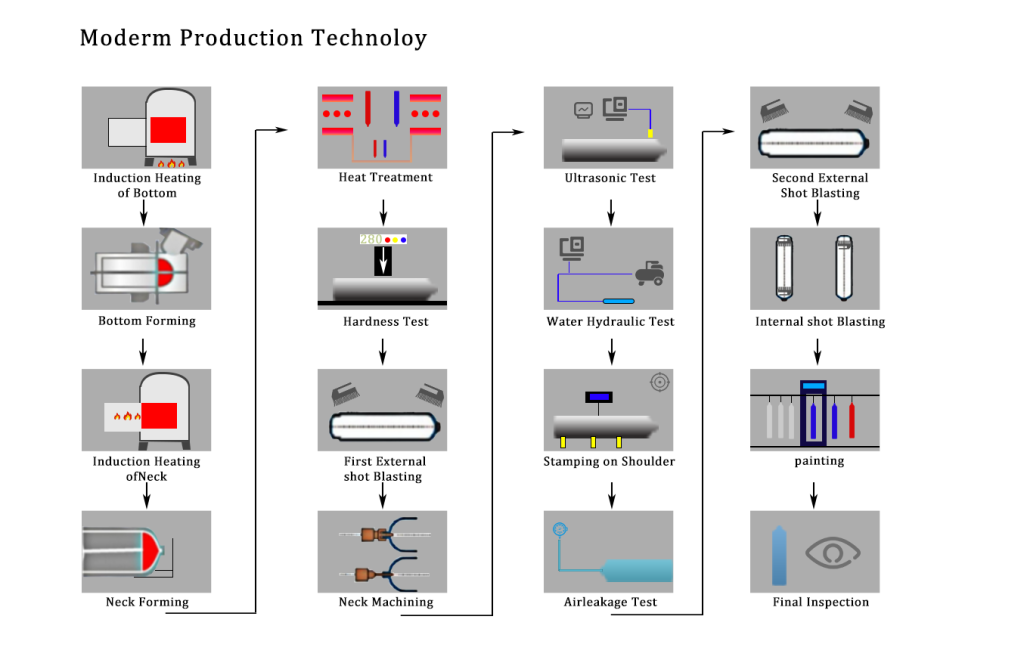

High-pressure Cylinder Manufacturing Process

Our seamless steel cylinders, crafted from premium seamless steel tubes, are manufactured using advanced rotary forming (Hot Spinning) technology. This cutting-edge technique enables us to precisely control cylinder length tolerance within 10mm, ensuring high dimensional accuracy. Each cylinder undergoes rigorous ultrasonic flaw detection, hydraulic testing, and air leakage testing to meet the highest safety and quality standards.

These high-strength steel cylinders deliver exceptional durability and safety, making them ideal for demanding applications across industrial, transportation, and automotive sectors. With precise manufacturing and stringent testing, our cylinders offer reliable performance under high-pressure conditions, positioning them as a trusted solution for industrial gas storage and compressed gas cylinders in diverse applications.

High-pressure Cylinder Manufacturing Process

Our seamless steel cylinders, crafted from premium seamless steel tubes, are manufactured using advanced rotary forming (Hot Spinning) technology. This cutting-edge technique enables us to precisely control cylinder length tolerance within 10mm, ensuring high dimensional accuracy. Each cylinder undergoes rigorous ultrasonic flaw detection, hydraulic testing, and air leakage testing to meet the highest safety and quality standards.

These high-strength steel cylinders deliver exceptional durability and safety, making them ideal for demanding applications across industrial, transportation, and automotive sectors. With precise manufacturing and stringent testing, our cylinders offer reliable performance under high-pressure conditions, positioning them as a trusted solution for industrial gas storage and compressed gas cylinders in diverse applications.

Why Choose Our High Pressure Gas Cylinders?

With over 37 years of manufacturing expertise in China, we are a trusted provider of industrial gas cylinders tailored for wholesale and industrial applications. Our cylinders are built to meet stringent international safety standards, ensuring secure storage and transportation of gases like oxygen, nitrogen, argon, CO2, and more. Designed with durability and performance in mind, they are the ideal choice for businesses that demand reliability.

Certified Quality

Our cylinders meet ISO, CE, and DOT standards for safety and reliability.

Custom OEM Services

We offer a wide range of sizes, branding, and packaging options to meet your specific business needs.

Competitive Bulk Pricing

Affordable solutions designed for wholesalers and B2B clients.

Comprehensive Storage Solutions

Custom 4×4 and 5×5 cylinder racks available to enhance safety and efficiency in storage and handling.

Why Choose Our High Pressure Gas Cylinders?

Certified Quality

Our cylinders meet ISO, CE, and DOT standards for safety and reliability.

Custom OEM Services

We offer a wide range of sizes, branding, and packaging options to meet your specific business needs.

Competitive Bulk Pricing

Affordable solutions designed for wholesalers and B2B clients.

Comprehensive Storage Solutions

Custom 4×4 and 5×5 cylinder racks available to enhance safety and efficiency in storage and handling.

With over 37 years of manufacturing expertise in China, we are a trusted provider of industrial gas cylinders tailored for wholesale and industrial applications. Our cylinders are built to meet stringent international safety standards, ensuring secure storage and transportation of gases like oxygen, nitrogen, argon, CO2, and more. Designed with durability and performance in mind, they are the ideal choice for businesses that demand reliability.

Custom OEM Solutions to Suit Your Business

As a factory specializing in OEM production, we offer fully customizable aluminum alloy gas cylinders to meet your specific branding and functional needs.

- Custom Sizes & Capacities: Create cylinders in sizes tailored to your market demand. Branding: Add your logo, brand colors, and labels for a unique product identity.

- Branding:Add your logo, brand colors, and labels for a unique product identity.

- Custom Packaging:Various packaging options designed to protect cylinders during transport and storage.

- Flexible Production: Small and large-scale OEM orders are welcomed with quick turnaround times.

Customized Gas Cylinder Solutions

——with Competitive Pricing and Efficient Storage Options

- Custom Sizes & Capacities Design cylinders that match your operational requirements.

- BrandingAdd your company logo, color, and labels for a distinct market presence.

- Packaging SolutionsCustom packaging to protect cylinders during transit and storage.

- Flexible Production Capable of handling both small and large-scale OEM orders with quick turnaround times.

- Bulk Discounts Special pricing for large orders tailored to your business.

- Flexible Payment TermsWe offer tailored payment options to fit your operational needs.

- Fast Delivery Robust logistics network to ensure your order arrives securely and on time, anywhere in the world.

- Tailored Racks Customizable to fit different cylinder sizes and capacities.

- Enhanced SafetyDesigned to maximize space while ensuring safe storage and easy access.

- Durable ConstructionBuilt with high-quality materials to withstand industrial environments.

Customized Gas Cylinder Solutions

——with Competitive Pricing and Efficient Storage Options

- Custom Sizes & Capacities Design cylinders that match your operational requirements.

- BrandingAdd your company logo, color, and labels for a distinct market presence.

- Packaging SolutionsCustom packaging to protect cylinders during transit and storage.

- Flexible Production Capable of handling both small and large-scale OEM orders with quick turnaround times.

- Bulk Discounts Special pricing for large orders tailored to your business.

- Flexible Payment TermsWe offer tailored payment options to fit your operational needs.

- Fast Delivery Robust logistics network to ensure your order arrives securely and on time, anywhere in the world.

- Tailored Racks Customizable to fit different cylinder sizes and capacities.

- Enhanced SafetyDesigned to maximize space while ensuring safe storage and easy access.

- Durable ConstructionBuilt with high-quality materials to withstand industrial environments.

Reliable High-Pressure Gas Cylinders for Diverse Industries

Our cylinders, produced using advanced processes and subjected to strict quality checks, meet international standards and are widely used across various industries, including manufacturing, medical, food and beverage, and scientific research. Their robust design ensures durability in demanding industrial environments.

International Standards

Our cylinders comply with ISO, CE, and DOT certifications.

Strict Testing

Each cylinder undergoes pressure, leak, and corrosion resistance tests to ensure durability and safety.

Long Service Life

Made from premium materials to provide long-lasting performance, reducing long-term costs for your business.

Custom Solutions

Adaptable cylinders designed for specific gases and industrial applications.

Industries Served

Manufacturing, medical, food processing, scientific research, and more.

Can I order custom-branded gas cylinders for my business?

Yes, we offer full OEM services, including branding, custom sizes, and tailored packaging options.

What is the minimum order quantity for wholesale?

The minimum order quantity depends on the specific cylinder size and customization requirements. Contact us for a detailed quote.

How do you ensure the safety and quality of your cylinders?

Our cylinders undergo strict quality control processes, including pressure testing, leak detection, and corrosion resistance checks, and comply with ISO, CE, and DOT standards.

Ready to Place Your Bulk Order?

Connect with our sales team to discuss your wholesale and custom OEM requirements. We are here to provide tailored solutions for your business.