Dewar Tanks for Cryogenic Liquids

Minnuo’s DPL and DPW series cryogenic Dewar tanks are vacuum-insulated stainless steel containers, ideal for storing and transporting liquid oxygen, nitrogen, and argon. Widely used in machinery, medical, electronics, food processing, and scientific research.

Our Industrial Dewar

DPL700-3.17

- Working pressure :3.17MPa

- Empty weight of container:395/417/444kg

- Nominal volume/effective volume :(175/166)L(195/185)L(210/199)L

DPW650-2.5

- Working pressure:2.5MPa

- Empty weight of container: 364/380/400kg

- Nominal volume/effective volume :(175/166)L(195/185)L(210/199)L

DPL450-2.3

- Working pressure:2.3MPa

- Empty weight of container: 132/140/147kg

- Nominal volume/effective volume :(175/166)L(195/185)L(210/199)L

DPL450-2.01

- Working pressure :2.01MPa

- Empty weight of container:125/133/140kg

- Nominal volume/effective volume :(175/166)L(195/185)L(210/199)L

DPL450-Ⅰ-1.4

- Working pressure :1.4MPa

- Empty weight of container: 70/79/84/88kg

- Nominal volume/effective volume: (175/166)L(195/185)L(210/199)L

DPL450-II-2.3

- Working pressure:2.88MPa

- Empty weight of container: 83/93/108/113kg

- Nominal volume/effective volume: (175/166)L(195/185)L(210/199)L

DPL450-1.4

- Working pressure :1.4MPa

- Empty weight of container: 109/116/121kg

- Nominal volume/effective volume: (175/166)L(195/185)L(210/199)L

DPL450-2.88

- Working pressure:2.88MPa

- Empty weight of container: 143/155/162kg

- Nominal volume/effective volume: (175/166)L(195/185)L(210/199)L

Your Trusted Supplier of Dewar Flask

Our welded adiabatic gas cylinder series features a double-layer structure with an adiabatic layer between the inner and outer cylinders, equipped with multi-layer insulating materials and maintained under high vacuum.

We have compiled a comprehensive set of product parameters to help you easily compare our various Dewar tank models.

- High Storage Capacity: Available in 410L, 450L, and 500L volumes with a working pressure of 2.5MPa.

- Enhanced Safety: Low usage and storage pressure ensures high security.

- Premium Design: Clean, sleek appearance with no filling or environmental pollution.

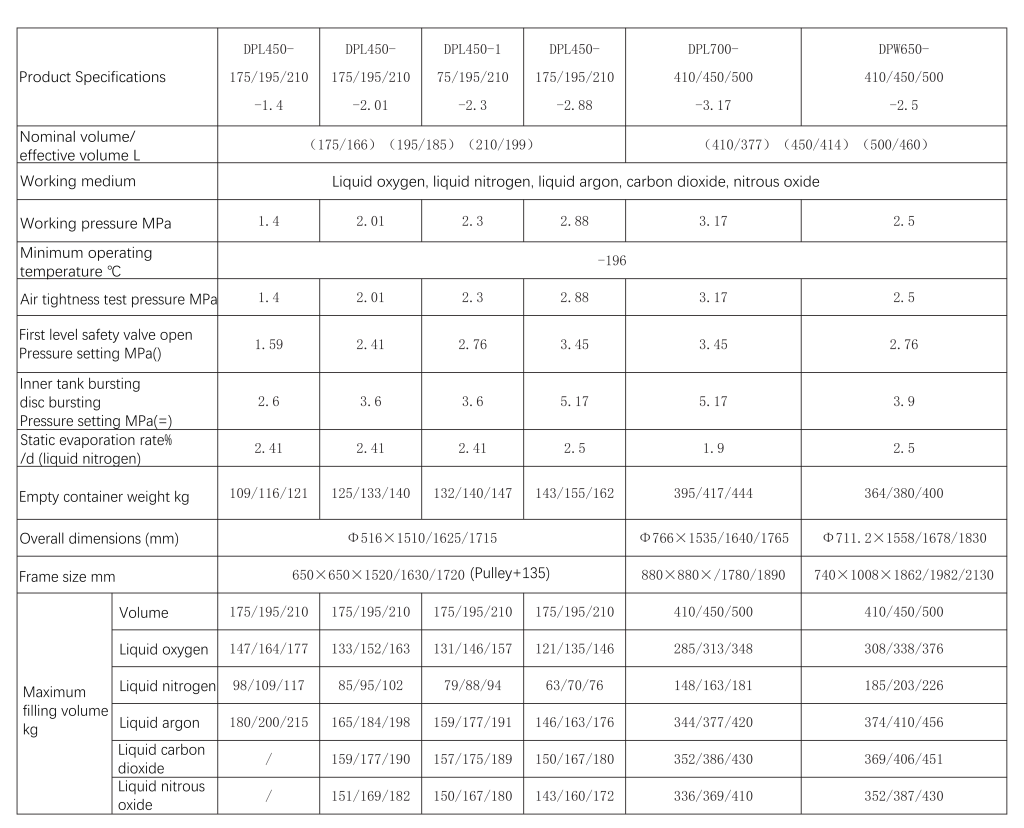

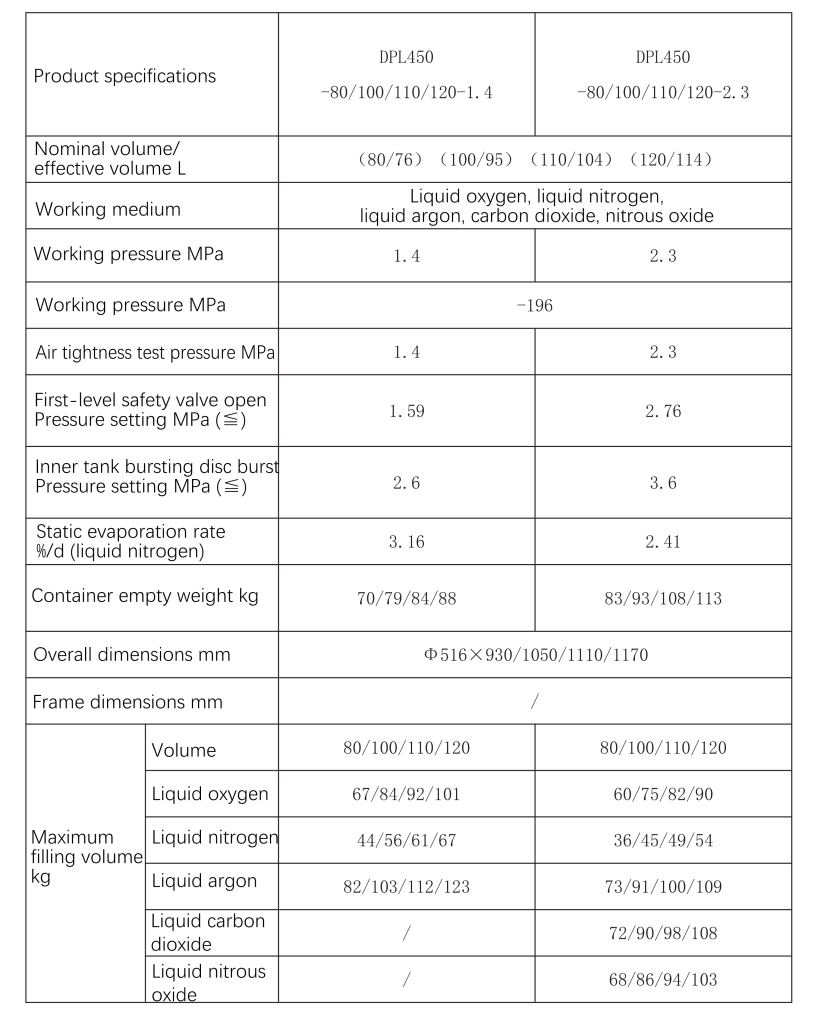

Dewar Flask Specifications: Unveiling the Technical Details of Our Cryogenic Storage Solutions

| Product Specification | DPL450-175/ 195/ 210-1.4 |

DPL450-175/ 195/ 210-2.01 |

DPL450-175/ 195/ 210-2.3 |

DPL450-175/ 195/ 210-2.88 |

DPL700-410/ 450/ 500-3.17 |

DPW650-410/ 450/ 500-2.5 |

DPL450-80/ 100/110/ 120-1.4 |

DPL450-80/ 100/110/ 120-2.3 |

|

|---|---|---|---|---|---|---|---|---|---|

| Nominal volume / effective volume (L) |

(175/166)(195/185) (210/199) |

(410/377)(450/414) (500/460) |

(80/76)(100/95) (110/104)(120/114) |

||||||

| Working medium | Liquid Oxygen | ||||||||

| Liquid Nitrogen | |||||||||

| Liquid Argon | |||||||||

| Carbon Dioxide | |||||||||

| Nitrous Oxide | |||||||||

| Working pressure MPa |

1.4 | 2.01 | 2.3 | 2.88 | 3.17 | 2.5 | 1.4 | 2.3 | |

| Minimum working temperature ℃ |

-196 | ||||||||

| Tightness test pressure MPa |

1.4 | 2.01 | 2.3 | 2.88 | 3.17 | 2.5 | 1.4 | 2.3 | |

| Safety valve opening pressure setting MPa(≤) |

1.59 | 2.41 | 2.76 | 3.45 | 3.45 | 2.76 | 1.59 | 2.76 | |

| Rupture disc burst pressure setting MPa(≤) |

2.6 | 3.6 | 3.6 | 5.17 | 5.17 | 3.9 | 2.6 | 3.6 | |

| Static evaporation rate (liquid nitrogen) |

2.41 | 2.41 | 2.41 | 2.5 | 1.9 | 2.5 | 3.16 | 2.41 | |

| Empty weight of container (KG) |

109/116/121 | 125/133/140 | 132/140/147 | 143/155/162 | 395/417/444 | 364/380/400 | 70/79/84/88 | 83/93/108/113 | |

| Overall dimension (mm) |

Φ516×1510/ 1625/1715 |

Φ766×1535/ 1640/1765 |

Φ711.2×1558/ 1678/1830 |

Φ516×930/1050/ 1110/1170 |

|||||

| Frame size (mm) |

650×650×1520 /1630/1720 (Belt wheel +135) |

880×880×1780 /1890 |

740×1008×1862 /1982/2130 |

/ | |||||

| Maximum filling capacity (KG) |

Volume | 175/195/210 | 175/195/210 | 175/195/210 | 175/195/210 | 410/450/500 | 410/450/500 | 80/100/110/120 | 80/100/110/120 |

| Liquid Oxygen | 147/164/177 | 133/152/163 | 131/146/157 | 121/135/146 | 285/313/348 | 308/338/376 | 67/84/92/101 | 60/75/82/90 | |

| Liquid Nitrogen | 98/109/117 | 85/95/102 | 79/88/94 | 63/70/76 | 148/163/181 | 185/203/226 | 44/56/61/67 | 36/45/49/54 | |

| Liquid Argon | 180/200/215 | 165/184/198 | 159/177/191 | 146/163/176 | 344/377/420 | 374/410/456 | 82/103/112/123 | 73/91/100/109 | |

| Liquid Carbon Dioxide | / | 159/177/190 | 157/175/189 | 150/167/180 | 352/386/430 | 369/406/451 | / | 72/90/98/108 | |

| Liquid Nitrous Oxide | / | 151/169/182 | 150/167/180 | 143/160/172 | 336/369/410 | 352/387/430 | / | 68/86/94/103 | |

The Complete Buyer’s Guide to liquid nitrogen cylinder

Embrace the future of gas storage with our innovative Dewar Tanks – designed for unmatched safety, efficiency, and reliability across industrial, medical, and other applications.

Why Choose Our Liquid Nitrogen Tank?

- Advanced Technology:Engineered for precise temperature control and pressure management to keep gases at optimal conditions for extended periods.

- Cost-Effective:Reduce the need for frequent refills, enhancing operational efficiency.

- Versatile Applications:Ideal for industrial, medical, and scientific use.

Ready to Make the Right Choice?

Whether you’re looking to import or purchase Dewar Tanks for your project or wholesale distribution, our comprehensive guide provides all the information you need to make an informed decision.

Safety Guidelines for Dewar Tanks Operation

Nitrogen and argon leaks can dilute oxygen in the air, leading to severe health risks, including shock or death. Always ensure proper ventilation in work areas.

When using liquid oxygen, use compatible equipment and keep it clean to avoid accidents. Improper handling can cause serious damage to the cylinder and injuries.

Cryogenic liquids can harm the human body. Always use eye and skin protection, such as safety goggles, face shields, long sleeves, and easy-to-remove gloves. Cryogenic liquids are extremely cold, at temperatures below -184°C.

Our containers are pressure vessels. Always ensure pressure is fully relieved before maintenance. Cold gas or liquid release can cause injuries.

Install safety valves in cryogenic liquid lines. Use appropriate safety measures to prevent gas expansion, which can rupture hoses or lines.

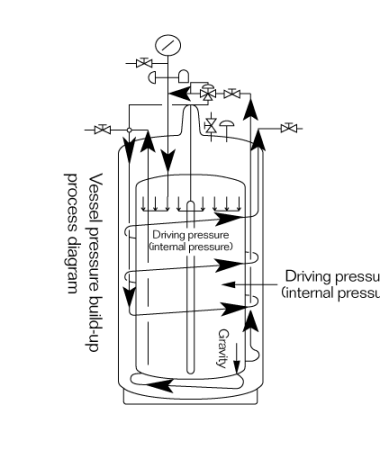

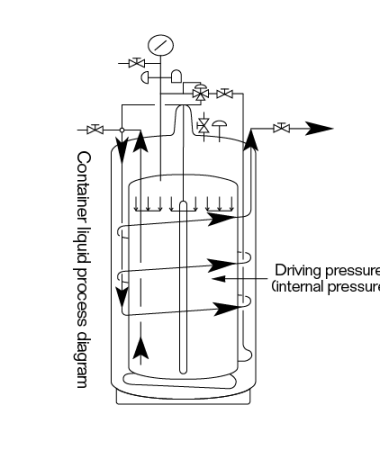

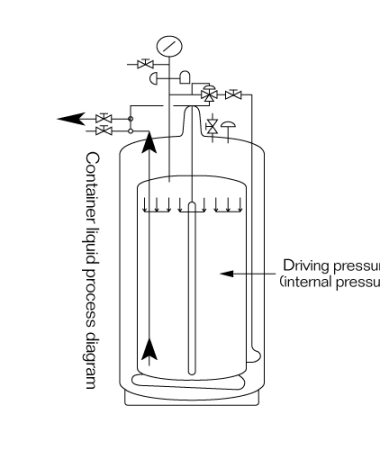

Unlock the Science Behind the DPL Series: A Deep Dive into Operational Principles

Our DPL series Dewar tanks come in various sizes, capable of storing different liquid volumes and providing both liquid and gas outputs. Below, we break down their operational principles, complemented by a schematic workflow to showcase key components and processes.

Pressure Build-Up Process

Gas Discharge Process

Liquid Discharge Process

our services

Custom marketing solutions

1. Quality Assurance & Free Maintenance

2. Dedicated Customer Management

3. 24/7 Customer Support Line

4. Lifetime Maintenance Services

Our Manufacturing Strength

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, we are equipped with the latest automated production lines and advanced vacuum insulation technology. Our annual production capacity exceeds 20,000 Dewar Tanks, allowing us to meet the needs of clients of all sizes.

- Advanced Equipment: Our factory is equipped with cutting-edge machinery to ensure precision in every step of production.

- Quality Certifications: We are ISO9001 certified and hold various industry-specific certifications, reflecting our commitment to quality and safety.

- Rigorous Quality Control: Every Dewar Tank undergoes a series of strict quality inspections, including vacuum testing and pressure integrity checks, to guarantee optimal performance.

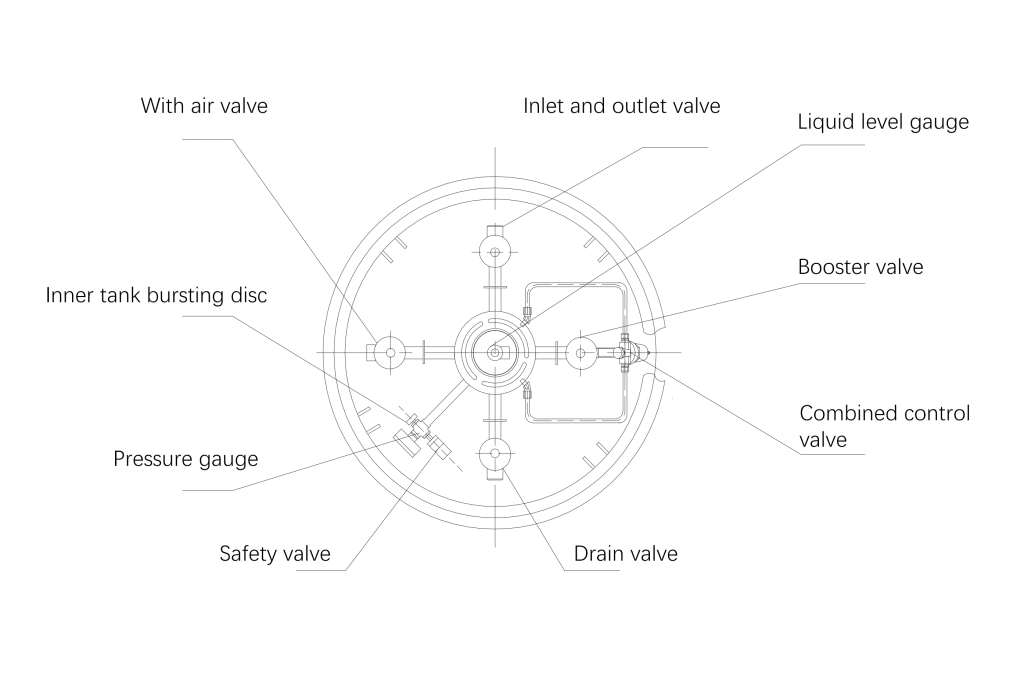

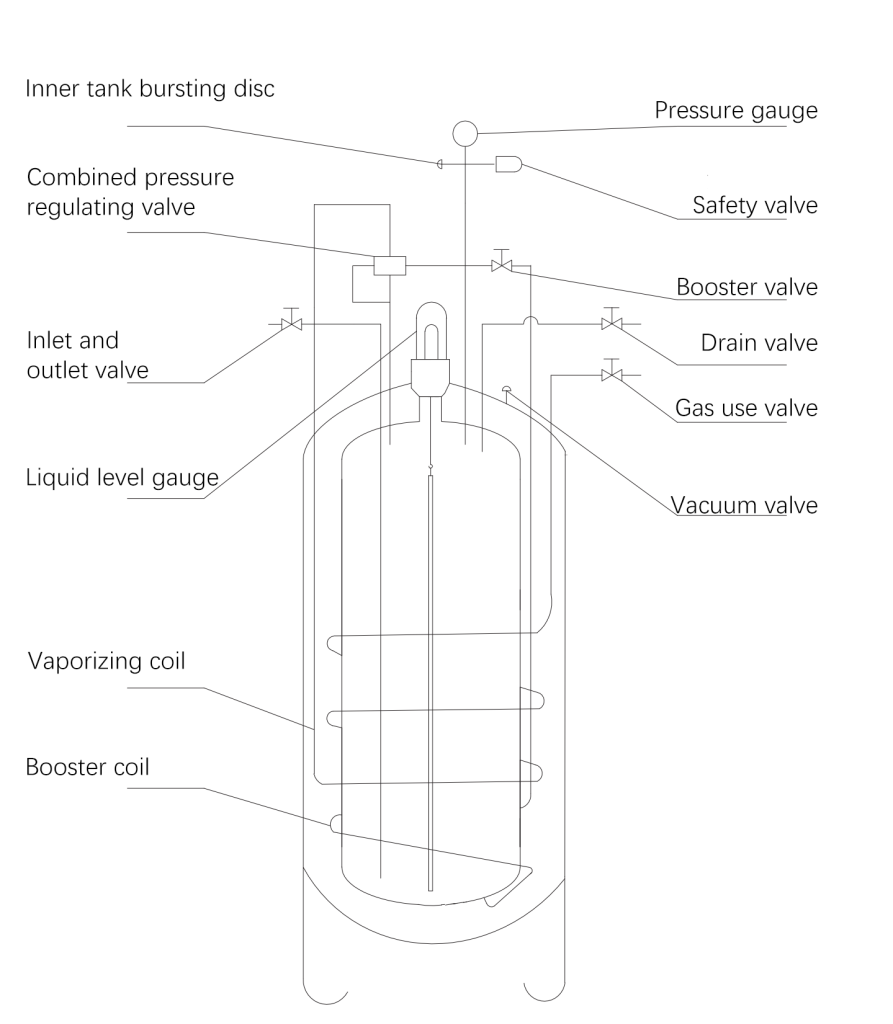

Component Structure Diagram

The different sizes in the DPL range can store different volumes of liquids and these cylinders are capable of delivering both liquids and gases. The various properties of the cylinders are realized by the following components, and we provide you with a schematic diagram of the workflow and the location of the components:

Experience the difference with our advanced Dewar Tanks

Engineered for exceptional durability and reliability, ensuring your gas storage needs are met with precision and efficiency. Reach out now for a tailored solution that exceeds your expectations.

Contact Us

Need to get in touch with us? Either fill out the form with your inquiry

We offer a range of Gas Cylinder solutions

“*” is a required field