- Home /

- Support

Support

At Minnuo, we take pride in offering exceptional customer service alongside our reliable products, including LPG cylinders, oxygen tanks, CNG containers, and more. Whether you need technical support, product information, or assistance with an order, our team is here to ensure you have the guidance and expertise you need. Explore our support resources and let us help you get the most out of our innovative solutions. We’re committed to your success!

- Care & maintenance

- Resources & regulations

- Policies & certificates

- Technical bulletins

- Warranty information

- FAQs

Maintenance guide: ensuring cylinder safety and durability

The key to keeping gas cylinders safe and prolonging their life is regular maintenance. Our maintenance services include thorough inspections, cleaning, pressure testing and repairs as necessary. Trust our team of professionals to provide the best care for your gas cylinders.

Regulatory Compliance: Gas Cylinder Safety Standards and Compliance

Resources and regulations

We understand the importance of complying with industry regulations. This section provides up-to-date regulatory information on the use, storage and transport of gas cylinders to ensure that your operations comply with national and international safety standards.

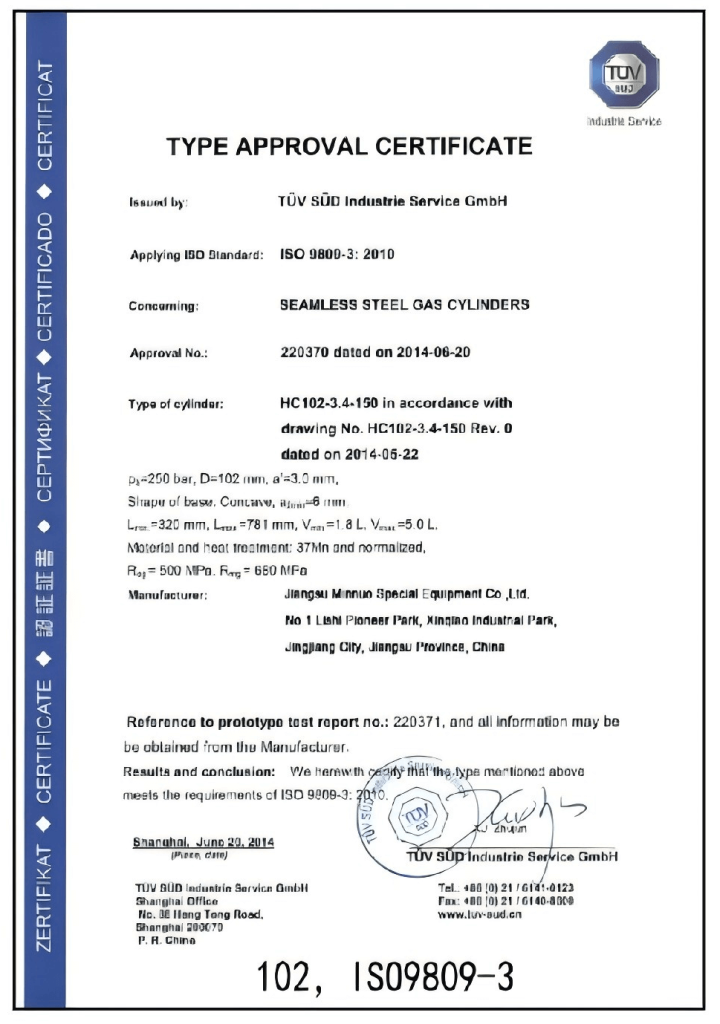

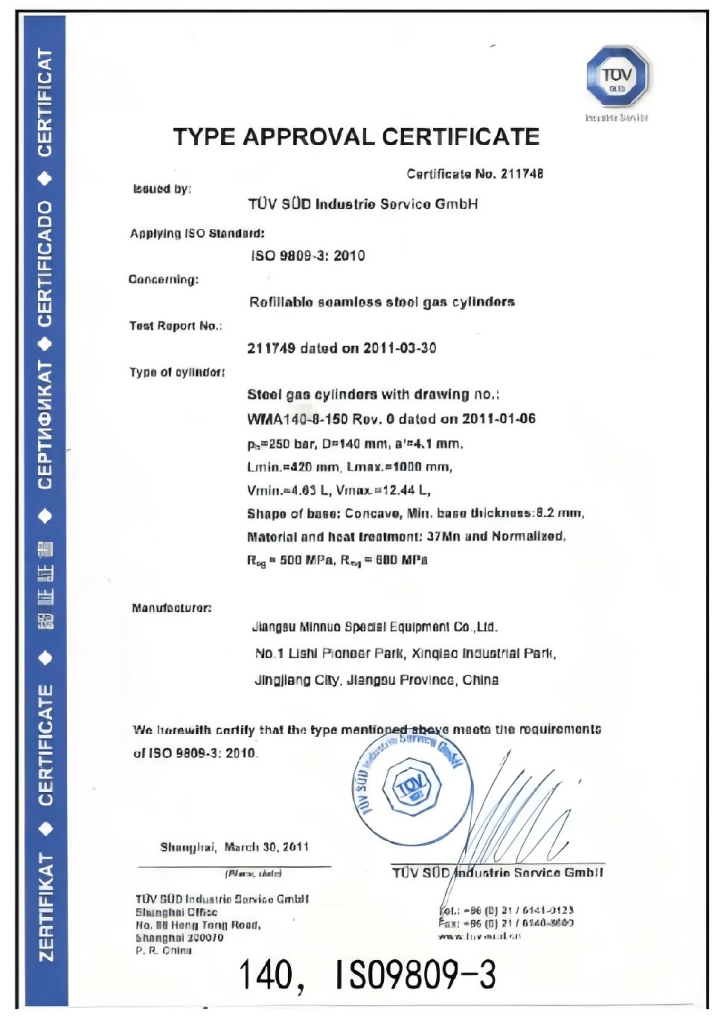

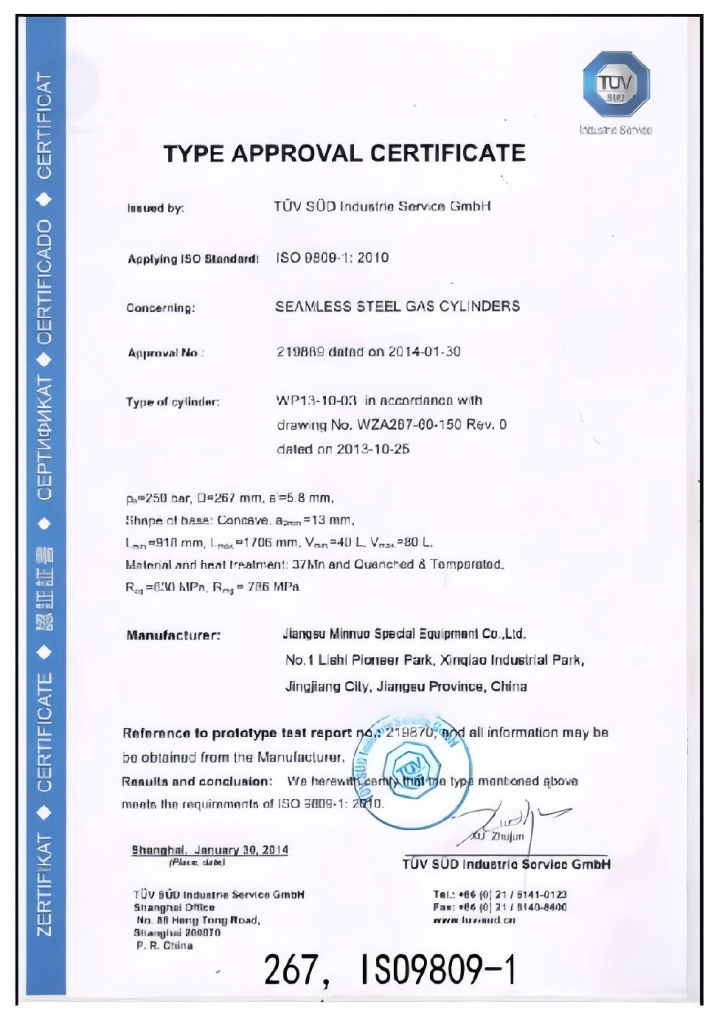

Policies and certificates

We proudly display a range of industry accreditations and certificates that demonstrate our commitment to quality and safety. From ISO accreditation to professional training certificates, we are committed to providing the highest standards of products and services.

Safety instructions for our products

Safety Instructions

WARNING: MAINTAIN AIR CIRCULATION: Nitrogen and argon gas leaking into the atmosphere can dilute the concentration of life-sustaining oxygen, and exposure to this oxygen-depleted environment may result in shock or severe brain damage, including death.

When the medium in the cylinder is liquid oxygen, parts and equipment compatible with liquid oxygen must be used and cleaned to be compatible with oxygen. Failure to follow these requirements may result in serious damage to the cylinder and injury to personnel.

Deep Cold Conditions: Cold gases and liquids can be harmful to the human body. When handling containers or transferring liquids, or under any circumstances, provide effective eye and skin protection, wear safety goggles or face shield when discharging liquids or gases, and for skin protection, long-sleeved clothing and easy-to-remove gloves are recommended. Cryogenic liquids at normal atmospheric pressure are -184 degrees Celsius or less.

PRESSURE HAZARD: The containers involved in this company are pressure vessels, and cold gas or cold liquids escaping from them due to a sudden release of pressure, or discharged portions of them during operation, can cause injury. When repairing these containers, make sure that the full pressure inside the container has been relieved and that the liquid inside the container has been evaporated to ensure that no pressurization occurs.

SPECIAL CAUTION: Install safety valves in cryogenic liquid lines, and when assembling lines or filling hose assemblies, install an appropriate safety valve in each section of line between shutoff valves, to prevent expansion of collected liquefied gases as they warm up and possible rupture of the hose or line, resulting in damage or injury.

*The terminology used in this manual is as follows:

Warning: Description of conditions capable of causing injury or death.

Note: Description of conditions that can cause damage to parts and quality or statement of information to be aware of.

Please be sure to read this manual in detail and use our products in accordance with the instructions, such as violation of the instructions caused by the use of personnel and asset damage, our company does not assume responsibility.

There are two ways to use gas in our products

Gas is used directly from the cylinder

The supply of gas is one of the main functions of cryogenic insulated gas cylinders. After a cylinder has been filled with a liquid and transported by road, there is usually a high pressure in the inner liner, which can be supplied immediately by opening the gas-phase valve, or by opening the pressure-booster valve if a continuous gas supply is required.

Cylinders utilize a combination of regulating valves to automatically adjust the internal pressure. For example, on a medium pressure (MP) cylinder, when the pressure falls below the booster set pressure of 125 psig (the factory setting for the cylinder), open the booster valve and the modular regulator valve will automatically open and the liquid will enter the booster coil and vaporize, thus converting the liquid into gas into the inner chamber and causing the pressure to rise until the pressure in the inner chamber reaches 125 psig, at which time the regulator valve will close. If the cylinder is not used for a long time, the pressure will also rise slowly. When the pressure in the cylinder exceeds the economizer valve setting (140 psig), the economizer circuit opens and when the gas phase valve is opened to use the gas, the gas is discharged through the vaporizer coil.

The temperature of the gas in the exhaust line will increase due to the heat transfer from the outside, bringing the temperature of the exhaust gas close to the ambient temperature. When the pressure drops below the setting of the economy valve (140 psig), the economy circuit closes automatically: if the gas phase valve is opened to use the gas from the bottle, the liquid is converted to gas in the carburetor coil and supplied to the outside world in a gaseous state.

The regulator for medium pressure (MP) series cylinders is factory set at 125 psig (0.86 MPa). If the gas pressure needs to be stabilized at a pressure below 0.86 MPa, an appropriate pressure reducing valve can be connected in series with the outlet line of the gas phase valve of the cylinder.

To increase the gas supply capacity, two or more liquid vessels can be connected together to create a higher capacity gas supply system using a manifold attachment. The DPL series vessels can supply gas at flow rates of up to 9.2 m³/h at ambient temperature and pressure using only their built-in vaporizers. At low flow rates, the gas is supplied close to ambient temperature, and the temperature of the gas is proportionately reduced if the flow rate required is increased. If a larger vaporization volume is required, an external vaporizer accessory can be used.

When using high pressure series vessels, if too cold CO2 gas passes through the pressure regulator bore, or if the flow rate is too fast, dry ice blockage may easily form in the bore. In this case, an external vaporizer should be used on the front of the pressure regulator to ensure that the CO₂ gas is not too cold before entering the pressure regulator.

Taking liquid directly from the cylinder

When using liquid directly from the cylinder, first determine whether the pressure in the cylinder is higher than the maximum operating pressure of the liquid-using equipment, and let the liquid in the cylinder flow into the liquid-using equipment through the pipeline and valve by the pressure difference. Keep the pressure difference between the cylinder pressure and the liquid-using equipment within 0.1-0.2MPa. Too high a pressure difference will cause rapid vaporization of low-temperature liquids, resulting in material loss and endangering safety. Liquid transportation should follow the steps below:

- Connect the conveying pipe with the liquid-phase valve, and the conveying pipe is recommended to use vacuum adiabatic hose.

- Connect the other end of the piping to the liquid-using equipment.

- Open the liquid-phase valve on the gas cylinder, which regulates the size of the liquid flow.

- When the delivery is complete, close the valve of the receiving device, close the liquid phase valve of the gas cylinder and release the pressure in the delivery tube to zero.

- Remove the delivery tube from the receiving unit.

How to Increase Fluid Consumption: This series of cylinders will discharge approximately 14 liters/hour at the set pressure (125psi/0.86MPa). To increase the amount of liquid used, use the same method as to increase the amount of gas used.

Make sure the operator is properly wearing protective eyewear and gloves before transferring fluid. If delivering to an open, elevated container, keep pressure in the cylinder as low as possible and provide isolation to prevent splashing and hose chatter. To maintain a proper pressure differential between the cylinder and the fluid-using equipment, closely monitor the opening and closing of the booster valve. The piping and fluid-using equipment must be able to withstand temperatures as low as -196°C. The piping and fluid-using equipment must be able to withstand temperatures as low as -196°C.

Discover Safe and Efficient Dewar Tank Handling with Our Expert Guidance

DPL series containers are high-strength liquid cylinders consisting of an inner vessel and an outer vessel with an insulated vacuum sandwich between the inner and outer vessels.

Warning:

Never place the container upside down, sideways, or roll the cylinder through the cylinder base. Always ensure that containers are in a vertical upright position when transporting, handling or storing them.Any compression, dropping, overturning, collision, etc., may affect the good performance of the container insulation system and may result in serious injury. If the cylinder is accidentally dropped, fallen, collided, etc., slowly lift it back to the normal vertical position and immediately open the venting valve and the gas phase valve to release the gas pressure inside the cylinder and remove the liquid medium inside the cylinder as soon as possible. If you see liquid spraying from the outer cylinder, it means that the impact is serious and has caused internal leakage, ask personnel to stay away from it to prevent any injury to personnel, and return it to the manufacturer for disposal after ensuring that there is no danger of injury. If the container is being used as an oxygen service, it may be purged with inert gas (nitrogen). If the damage is obvious or cannot be clearly determined, contact the manufacturer through the seller and return the cylinder to the manufacturer with an explanation of the cause of the damage and ask the manufacturer to inspect the damage.

When loading or unloading containers from a delivery truck, use a cart, lifting frame, crane, or parallel loading bracket, and never lift containers by hand at an angle of less than 15°.

In order to move the container over bad ground or to lift the container, suitable transportation and lifting means and devices must be used.

The top of the cylinder has a stainless steel protective ring designed to protect the piping valve components at the top. The stainless steel ring is supported on the cylinder by four brackets, two of which have an oblong hole in them. This oblong hole can be used for lifting the cylinder or hanging it on a transportation trolley. When it is necessary to lift the cylinder, use the appropriate hooks and hang them on the oblong holes of the two brackets and make sure that the cylinder is lifted vertically. Do not hang the protection ring directly.

Technical Update: What's New in the Gas Cylinder Industry

Technical Bulletin

As technology continues to advance, we regularly publish technical bulletins on the latest developments in cylinder design, materials and manufacturing processes. Follow our bulletins for cutting-edge information on the industry.

FAQ

What types of pressure vessels does Minnuo manufacture?

At Minnuo, we produce a wide range of pressure vessels including LPG cylinders, high-pressure gas cylinders, aluminum bottles, Dewar flasks, oxygen bottles, nitrogen bottles, and various other industrial gas cylinders. Our products meet stringent international standards to ensure safety and reliability across various industries.

What certifications do Minnuo’s pressure vessels meet?

Our pressure vessels adhere to international standards such as ISO 9809, DOT-3AA, TPED, KGS, GB, BVTUV and more. These certifications ensure our products are safe for use in different regions and industries, providing reliability and compliance with global safety regulations.

How does Minnuo ensure the quality of its gas cylinders?

At Minnuo, quality is a top priority. We use high-grade materials such as 34CrMo4 alloy steel and carbon composites, advanced manufacturing technologies, and stringent testing processes to ensure every cylinder meets or exceeds international safety standards. Our dedicated quality control team conducts thorough inspections at every stage of production.

What makes Minnuo stand out in the pressure vessel industry?

Minnuo is known for its high-quality products, adherence to international safety standards, and commitment to customer satisfaction. With a team of over 258 skilled workers and a state-of-the-art manufacturing facility, we provide innovative solutions tailored to meet the diverse needs of clients across the globe.

Can Minnuo customize gas cylinders according to specific requirements?

Yes, Minnuo offers customized solutions for clients who require specific sizes, capacities, or other unique features in their gas cylinders. We work closely with customers to develop tailored products that meet their exact needs.

How does Minnuo handle safety when manufacturing pressure vessels?

Safety is our top priority at Minnuo. Our pressure vessels are manufactured using the highest quality materials and are tested rigorously under various pressure conditions. We also adhere to international safety standards such as ISO 9809, DOT-3AA, and TPED to guarantee the highest level of product safety.

How can I get in touch with Minnuo for a quote or more information?

For any inquiries regarding quotes, product details, or other services, you can reach out to us via our contact form on the website, or directly through email or phone. Our customer service team will respond promptly to provide the information you need.

Are Minnuo’s pressure vessels suitable for industrial, medical, and commercial applications?

Yes, Minnuo’s gas cylinders are designed for a wide range of applications, including industrial, medical, and commercial uses. Our products are ideal for industries like manufacturing, healthcare, energy, and gas distribution, ensuring safe and efficient gas storage and transportation.