The food processing industry frequently faces the challenge of equipment upgrades. Many companies overlook the crucial role of the reactors in food Industry, leading to the accumulation of small issues during production that eventually turn into major problems. In fact, the selection and use of the reactor are directly related to the stability of product quality and production efficiency, especially when dealing with temperature-sensitive and viscous materials. So, how can you choose the right reactor to maximize production efficiency?

Reactors have a wide range of applications in the food industry. They not only ensure precise temperature control but also provide effective mixing and sealing, meeting the needs of different stages in food processing. They are widely used in sauce production, dairy fermentation, juice concentration, candy manufacturing, and more.

Next, let’s dive into the working principle of the reactor and explore how to choose the most suitable equipment for your needs.

Working Principle of Reactors in the Food Industry

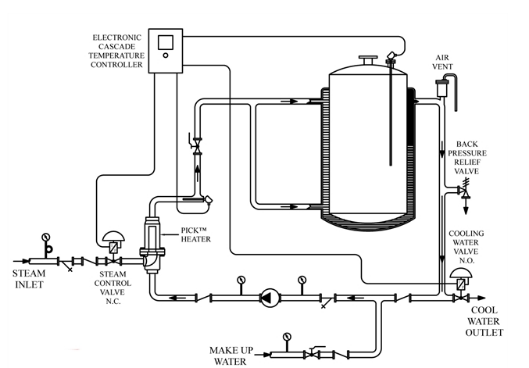

A reactor is a comprehensive device equipped with sealing, heating, mixing, and reaction capabilities, with its core function being the precise transfer of heat and energy. It mainly achieves key food processing operations through the following aspects:

Heating and Temperature Control

Reactors typically use jacket heating ( hot water ) or electrical heating to achieve precise temperature control. This is particularly important in the food industry; for example, syrup concentration requires a specific temperature range, as too high or too low temperatures can affect the quality of the final product.

Uniform Mixing

The built-in mixing system ensures that materials are fully blended, improving reaction uniformity. This is especially important for viscous materials (such as chocolate or jam), as it helps avoid local overheating or burning issues.

Sealing and Sterile Environment

The sealing performance of the reactor makes it highly favored in food processing that requires sterile operations, such as fermentation of dairy products or sterilization of beverages.

Pressure Regulation

Certain food processing operations require either a pressurized or vacuum environment. The reactor can achieve this by adjusting the pressure to enable cooking, concentration, or vacuum degassing.

Applications of Reactors in Food Industry

Sauce and Condiment Production

In the production of condiments such as soy sauce, vinegar, ketchup, and hot sauce, reactors play an irreplaceable role. These processes require precise temperature control and uniform mixing, both of which are often difficult to achieve with traditional equipment.

- Precise temperature control ensures even heating of materials, preventing localized burning and enhancing the flavor and texture of the sauces.

- The mixing and scraping wall design effectively handles high-viscosity materials, preventing sticking and waste, thereby improving production efficiency.

In addition, the stainless steel material and sealing design of the reactor ensure food-grade hygiene standards, providing peace of mind during the processing.

Dairy Fermentation

The fermentation process of dairy products requires extremely strict temperature control, as even slight deviations can affect product quality. Reactors can provide a constant temperature and sterile environment for microorganisms like lactic acid bacteria, ensuring stable and efficient fermentation.

- The temperature control system keeps yogurt and cheese fermentation within the optimal range, maintaining microbial activity.

- The sealing design isolates external contamination, meeting the high hygiene standards required for dairy processing.

The automated control function also reduces the uncertainty of manual operation, making it easier to manage complex fermentation processes.

Beverage and Juice Concentration

The core of juice concentration lies in the ability to rapidly remove water while preserving the natural nutrients and flavor of the juice. This is a challenge for traditional equipment, but reactors solve this problem through low-temperature vacuum concentration technology.

The reactor can evaporate water at low temperatures, reducing damage to nutrients caused by high temperatures. At the same time, the stirring function ensures uniform heating of the materials. Furthermore, the vacuum environment minimizes oxidation, preserving the color and flavor of the juice, bringing your product closer to its natural quality.

Candy Production

In candy production, the cooking and mixing of sugar syrup are often the most challenging steps. Reactors help stabilize this process through precise temperature control and efficient mixing.

- The temperature control system precisely adjusts the syrup’s cooking temperature, avoiding crystallization or burning issues.

- The stirring device ensures thorough mixing of the syrup and additives, improving product consistency and taste.

This not only ensures smooth appearance and stable quality of the candy but also significantly increases production efficiency and reduces the rate of defective products.

Jam and Fruit Puree Processing

Processing high-viscosity jams and fruit purees has always been a challenge, especially when material sticking and localized burning lead to inefficiency or product wastage. Reactors solve these issues through scraping mixing and precise heating.

The vacuum function further reduces oxidation, preserving the natural color and flavor of the jam and puree. Additionally, this processing method extends the shelf life of the product, making it more competitive in the market.

How to Choose the Right Reactor?

When selecting a reactor, food companies should consider four key factors: process requirements, material characteristics, hygiene standards, and operational convenience.

Determine Process Requirements

- Do you need a specific temperature range or precise temperature control?

- Are you dealing with high-viscosity materials that require higher stirring torque?

- Is vacuum operation or pressure adjustment necessary?

Choose the Appropriate Material

- Since food processing equipment requires high hygiene standards, it is recommended to choose materials such as 304 or 316L stainless steel, which offer better corrosion resistance and are easier to clean.

- For acidic or high-salt foods (such as vinegar or soy sauce), 316L stainless steel is more corrosion-resistant.

Capacity and Size Matching

- Select the appropriate capacity based on production scale. For example, small laboratory setups may require reactors ranging from 10L to 100L, while large-scale industrial production would require reactors of 500L or more.

Safety and Certification

- Ensure the equipment is food-grade certified (e.g., FDA, GMP) and is equipped with necessary safety features, such as overpressure protection valves and temperature overload alarms.

After-Sales Service and Support

- Quality after-sales services (e.g., regular maintenance, repair support) can significantly extend the equipment’s lifespan and reduce long-term costs.

- Pay attention to supporting elements like the selection of stirring paddles (e.g., anchor, paddle type) and automated control systems (e.g., PLC).

Common Issues When Using Reactors in Food Processing

How to Avoid Material Sticking to the Walls and Overheating?

When processing high-viscosity foods (like jam or syrup), materials are prone to sticking to the reactor walls, causing uneven heating or localized overheating.

- Choose a reactor with a scraping function for the stirrer paddle, which can periodically remove material that adheres to the walls.

- Install an accurate temperature control system to prevent local overheating. Steam jackets or thermal oil systems are ideal choices for even temperature distribution.

- For materials that are particularly prone to sticking, select a reactor with food-grade non-stick coating on the reactor walls to further reduce sticking risks.

Can a Reactor Handle Different Types of Materials Simultaneously?

In theory, a reactor can process multiple types of materials, but attention should be paid to the following:

- Material Compatibility: Ensure the reactor body material (such as stainless steel) can withstand the chemical properties of all processed materials. For example, acidic or high-salt foods may require more corrosion-resistant 316L stainless steel.

- Cross-Contamination Control: Processing multiple materials may lead to cross-contamination. It is recommended to use detachable stirrers and a CIP (Clean-In-Place) cleaning system to ensure thorough cleaning.

- Process Compatibility: Different materials may require varying processing conditions (such as temperature, stirring speed, or vacuum). Choose a reactor with a multifunctional control system that can adjust parameters to meet different requirements.

Should Food Industry Companies Pay Attention to Environmental Impact When Using Reactors?

With increasingly stringent environmental regulations, food companies need to consider the potential environmental impact of reactor usage:

- Wastewater Discharge:

- The cleaning process of reactors generates wastewater, especially when producing high-viscosity or high-pigment products (like syrups or jams). It is advisable to pair reactors with wastewater treatment systems to prevent direct discharge.

- Energy Consumption Control:

- Choose energy-efficient heating systems (such as high-efficiency steam heating or thermal oil systems) to reduce energy consumption.

- High-quality insulation designs can reduce heat loss and are an important means of lowering energy consumption.

- Noise and Vibration:

- Some reactors may produce noise or vibrations during operation, which could affect the working environment. When selecting a reactor, consider choosing equipment with low noise and vibration designs.

What is the Maintenance Cycle for Food Reactors?

The maintenance cycle for reactors is closely related to usage frequency and process requirements:

- Daily Inspections: Check seals, stirrer systems, temperature control devices, and pressure gauges to ensure proper operation.

- Quarterly Maintenance: Clean dirt from jacketed pipes and check for heating efficiency decline. Replace consumables like gaskets and shaft seals.

- Annual Overhaul: Inspect the reactor’s body for corrosion, cracks, or damage to welds. Upgrade software and hardware for control systems.

Tip: It’s recommended for you to maintain an equipment maintenance log, keeping detailed records of each maintenance activity to improve equipment management efficiency.

Conclusion

Choosing the right reaction vessel can significantly improve temperature control accuracy, material mixing uniformity, and production efficiency in food processing. Looking to choose a reactor for your food processing needs? Want to learn more about reaction vessel selection tips? Visit MINNUO website for free consultations and expert answers to help upgrade your food processing!